| Citation: | Guiquan Zhao, Pujia Cheng, Wenjin Huang, Hang Ma, Xin Wang, Rong Gu, Genfu Zhao, Lingyan Duan, Yongjiang Sun, Huaiyu Shao, Xiaoxiao Zou, Hong Guo. In-situ modification from surface to bulk for enhancing the performance of NCM811 cathode[J]. Energy Lab, 2025, 3(1): 240020. doi: 10.54227/elab.20240020 |

In-situ modification from surface to bulk for enhancing the performance of NCM811 cathode

-

Abstract

LiNi0.8Co0.1Mn0.1O2 (NCM811) cathode material has been widely applied mobile electronics products, electric vehicles, large-scale energy storage and so on. However, it is still necessary to develop a convenient strategy to resolve the challenges resulted from bulk (micro-stress, micro-cracks) to surface (side reactions) for advanced lithium-ion batteries. Herein, we develop a facile in-situ strategy to modify NCM811 with LiAlO2 coating on surface and Al doping in bulk. Especially, the LiAlO2 layer protect the active material from the erosion of air and electrolytes, while Al doping can effectively enlarge lattice spacing, restrain Li+/Ni2+ mixing, and reduces the microcracks within secondary particles. Two aspects significantly improve ambient tolerance, electrochemical performances and thermal stability over the bare counterpart. The optimized Al-modified NCM811 exhibits a discharge capacity of 197.3 mAh g−1 at 0.1 C, a well capability retention of 83.7% at 5.0 C, and a high capability retention of 92.1% after cycling at 1.0 C for 100 times. Furthermore, the exothermic temperatures increase from 271.3 °C to 277.3 °C, while the total heat generated from exothermic reactions reduce from

3985.0 J g−1 to3078.0 J g−1.-

Keywords:

- LiNi0.8Co0.1Mn0.1O2 /

- in-situ strategy /

- LiAlO2 coating /

- Al doping /

- micro-cracking.

-

-

References

1. B. W. Xiao, and Sun, X L, Adv. Energy Mater., 2018, 8, 1802057 2. R. Schmuch, R. Wagner, G. Hörpel, Nat. Energy, 2018, 3, 267 3. N. Y. Park, G. T. Park, S. B. Kim, ACS Energy Lett., 2022, 7, 2362 4. D. H. Cho, C. H. Jo, W. Cho, J. Electrochem. Soc., 2014, 161, A920 5. G. W. Nam, N. Y. Park, K. J. Park, ACS Energy Lett., 2019, 4, 2995 6. Y. J. Bi, J. H. Tao, Y. Q. Wu, L. Z. Li, Y. B. Xu, E. Y. Hu, K. Amine, Science, 2024, 384, 912 7. C. S. Yoon, H. H. Ryu, G. T. Park, J. Mater. Chem. A, 2018, 6, 4126 8. Y. R. Zhang, Y. Katayama, R. Tatara, L. Giordano, Y. Yu, D. Fraggedakis, J. G. Sun, F. Maglia, R. Jung, M. Z. Bazant, Y. Shao-Horn, Energy Environ. Sci., 2020, 13, 183 9. Y. Kim, D. Kim, S. Kang, Chemistry of Materials, 2011, 23, 5388 10. Y. J. Sun, W. J. Huang, G. F. Zhao, Q. Liu, L. Y. Duan, S. M. Wang, Q. An, H. Wang, H. Guo, ACS Energy Letters, 2023, 8, 1629 11. Y. J. Sun, C. H. Wang, W. J. Huang, G. F. Zhao, L. Y. Duan, Q. Liu, S. M. Wang, A. Fraser, H. Guo, X. L. Sun, Angew. Chem. Int. Ed., 2023, 135, e202300962 12. G. T. Park , B. Namkoong, S. B. Kim, J. Liu , C. S. Yoon, Y. K. Sun, Nat. Energy, 2022, 7, 946 13. Z. L. Xiao, C. H. Hu, L. B. Song, L. J. Li, Z. Cao, H. L. Zhu, J. Liu, X. Y. Li, F. L. Tang, Ionics, 2018, 24, 91 14. W. Liu, X. X. F. Li, D. B. Xiong, Y. C. Hao, J. W. Li, H. R. Kou, B. Yan, D. J. Li, S. G. Lu, A. Koo, K. Adair, X. L. Sun, Nano Energy, 2018, 44, 111 15. L. S. Li, Z. Zhang, S. H. Fu, Z. Z. Liu, Y. M. Liu, J. Alloys Compd., 2018, 768, 582 16. D. Wang, X. H. Li, Z. X. Wang, H. J. Guo, Y. Xu, Y. L. Fan, Electrochim. Acta, 2016, 196, 101 17. Y. Jiang, Y. J. Bi, M. Liu, Z. Peng, L. Y. Huai, P. Dong, J. G. Duan, Z. L. Chen, X. Li, D. Y. Wang, Y. J. Zhang, Electrochim. Acta, 2018, 268, 41 18. M. Jeong, H. Kim, W. Lee, S. J. Ahn, E. Lee, W. S. Yoon, J. Power Sources, 2020, 474, 228592 19. U. H. Kim , G. T. Park, B. K. Son, G. W. Nam, J. Liu, L. Y. Kuo, P. Kaghazchi , C. S. Yoon, Y. K. Sun, Nat. Energy, 2020, 5, 860 20. G. L. Xu, X. Liu, A. Daali, R. Amine, Z. H. Chen, K. Amine, Adv. Funct. Mater., 2020, 30, 2004748 21. A. V. Bommel, J. R. Dahn, J. Electrochem. Soc., 2009, 156, A362 22. Y. Wu, Y. F. Li, L. Y. Wang, Y. J. Bai, Z. Y. Zhao, L. W. Yin, H. Li, Electrochim. Acta, 2017, 235, 463 23. J. Z. Li, S. H. Luo, X. Y. Ding, Q. Wang, P. He, Mater. Lett., 2017, 196, 183 24. M. F. Zhang, G. R. Hu, L. W. Liang, Z. D. Peng, K. Du, Y. B. Cao, J. Alloys Compd., 2016, 673, 237 25. G. Y. Li, Z. J. Zhang, R. N. Wang, Z. L. Huang, Z. C. Zuo, H. H. Zhou, Electrochim. Acta, 2016, 212, 399 26. Y. J. Sun, Z. D. Liu, X. C. Chen, X. P. Yang, F. W. Xiang, W. Lu, Electrochimica Acta, 2021, 376, 138038 27. Y. D. Zhang, H. Li, J. X. Liu, J. C. Zhang, F. Y. Cheng, J. Chen, J. Mater. Chem. A, 2019, 7, 720958 28. Z. W. Fu, J. T. Hu, W. L. Hu, S. Y. Yang, Y. F. Luo, Appl. Surf. Sci., 2018, 441, 1048 29. S. Verdier, L. E. Ouatani, R. Dedryvère, F. Bonhomme, P. Biensan, D. Gonbeaua, J. Electrochem. Soc., 2007, 154, A1088 30. L. W. Liang, F. Jiang, Y. B. Cao, G. R. Hu, K. Du, Z. D. Peng, J. Power Sources, 2016, 328, 422 31. D. Wang, X. H. Li, Z. X. Wang, H. J. Guo, Z. J. Huang, L. K. Kong, J. J. Ru, J. Alloys Compd., 2015, 647, 612 32. Z. Z. Yu, G. Q. Zhao, F. L. Ji, H. Tong, Q. L. Tong, H. C. Li, Y. Cheng, Rare Metals, 2023, 42, 4103 33. D. S. Ko, J. H. Park, B. Y. Yu, D. Ahn, K. Kim, H. N. Han, W. S. Jeon, C. H. A. Jung, Adv. Energy Mater., 2020, 10, 2001035 34. J. H. Kim, H. H. Ryu, S. J. Kim, C. S. Yoon, Y. K. Sun, ACS Appl. Mater. Inter., 2019, 11, 30936 35. M. Yoon, Y. Dong, J. Y. Hwang, J. Sung, H. Cha, K. Ahn, Y. M. Huang, S. J. Kang, J. Li, J. Cho, Nat. Energy, 2021, 6, 362 36. H. F. Yu, Y. P. Cao, L. Chen, Y. J. Hu, X. Z. Duan, S. Dai, C. Z. Li, H. Jiang, Nat. Commun., 2021, 12, 4564 -

Rights and permissions

This is an open access article under the terms of the Creative Commons Attribution License, which permits use, distribution and reproduction in any medium, provided the original work is properly cited.

-

Supplementary Information

0020 Supplement+Information-modification

Information

Article Metrics

-

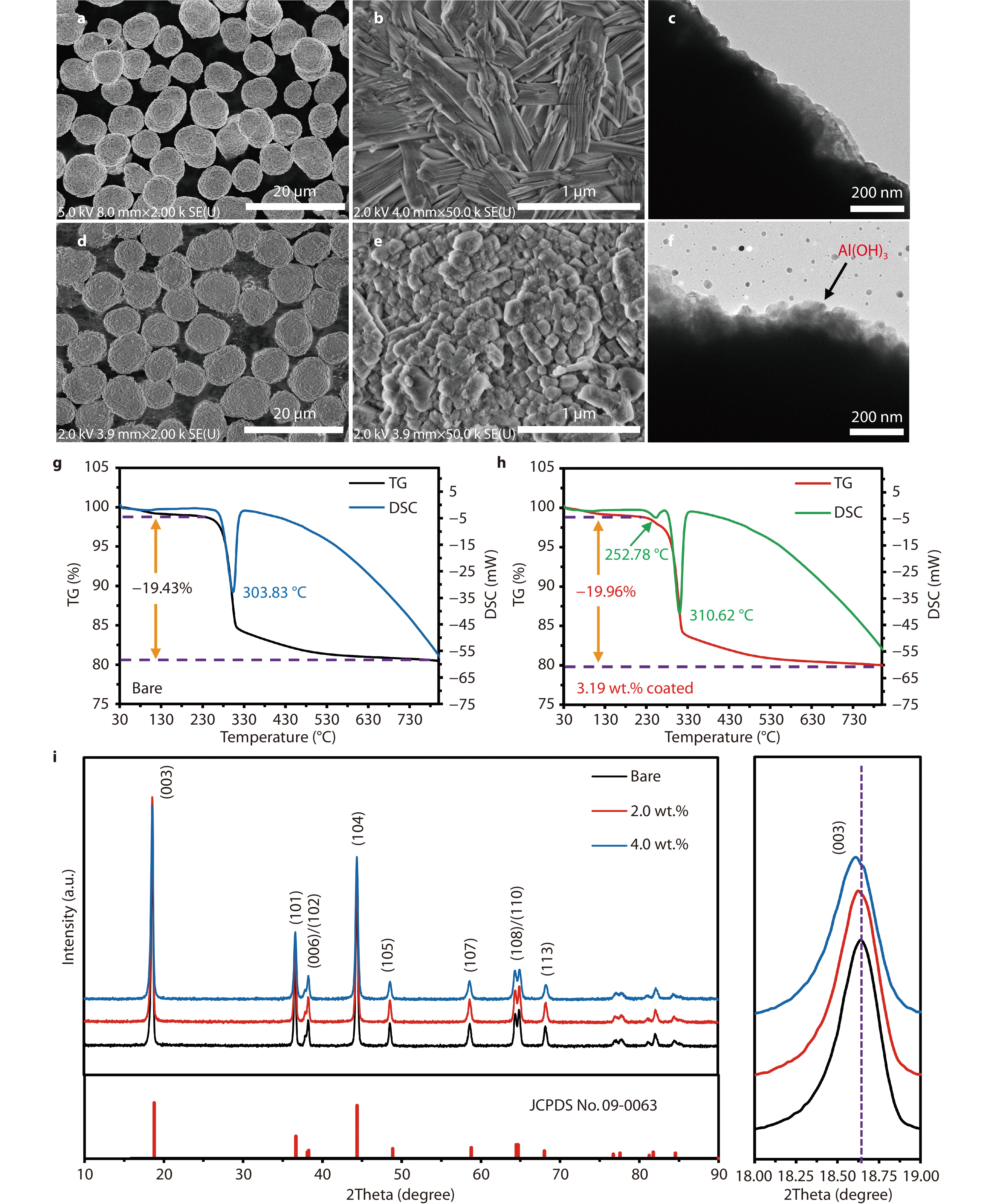

Figure 1.

SEM and TEM images of a-c bare and d-f 3.19 wt.% Al(OH)3-coated Ni0.8Co0.1Mn0.1(OH)2, TG/DSC curves of g bare and h 3.19 wt.% Al(OH)3-coated Ni0.8Co0.1Mn0.1(OH)2, i XRD patterns of bare and Al-modified NCM811 with various modification amounts.

-

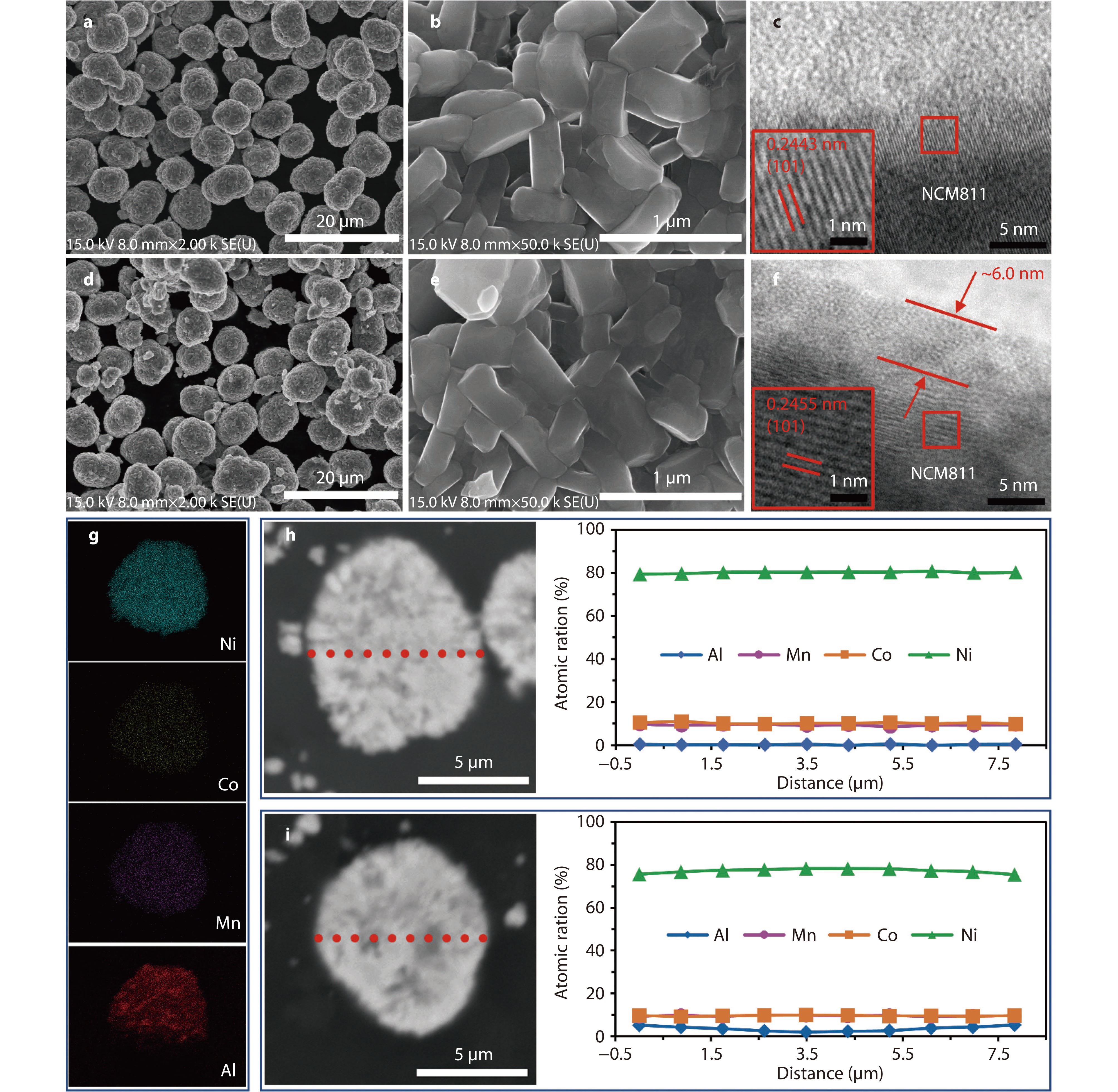

Figure 2.

a-c SEM and TEM images of bare and d-f 2.0 wt.% Al-modified NCM811, g EDS mappings of 2.0 wt.% Al-modified NCM811, the cross-sectional SEM images and the corresponding element distributions of single secondary particles from h bare and i 2.0 wt.% Al-modified NCM811.

-

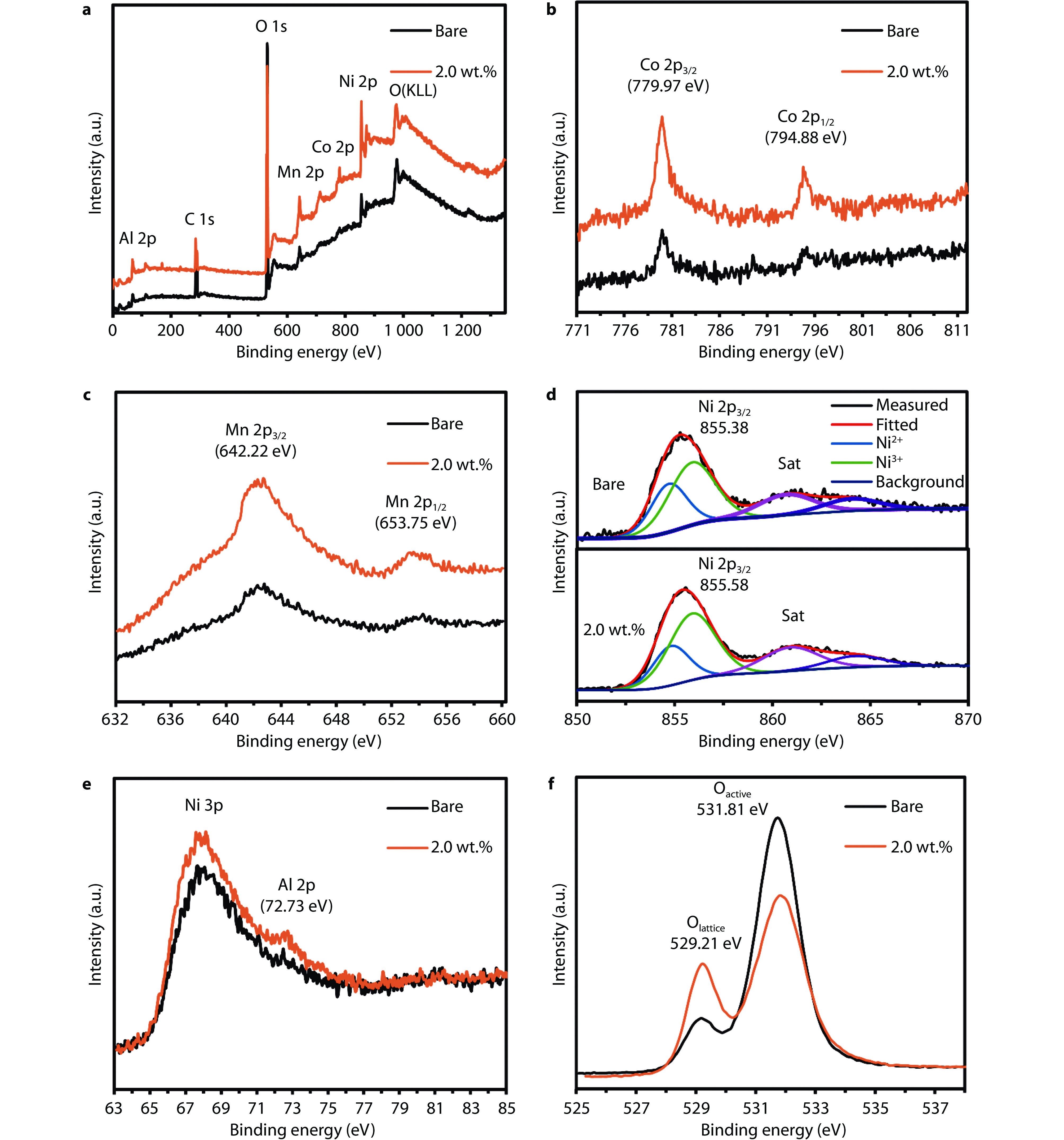

Figure 3.

XPS spectra of bare and 2.0 wt.% Al-modified NCM811. a Original survey spectra, b Co spectra, c Mn spectra, d Ni spectra, e Al spectra, and f O spectra.

-

Figure 4.

a Initial charge/discharge profiles of bare and Al-modified NCM811 at 0.1 C. b Discharge capacities of bare and Al-modified NCM811 obtained at different currents. c The lithium ions diffusion constant of bare and Al-modified NCM811 at 30 °C obtained by the GITT. d The comparation of long-term cycling performance in half-cells at 1.0 C in the range of 2.7-4.3 V. e, f The dQ/dV profiles of bare and 2.0 wt.% Al-modified NCM811 as a function of the number of cycles obtained by differentiating the charge-discharge curves.

-

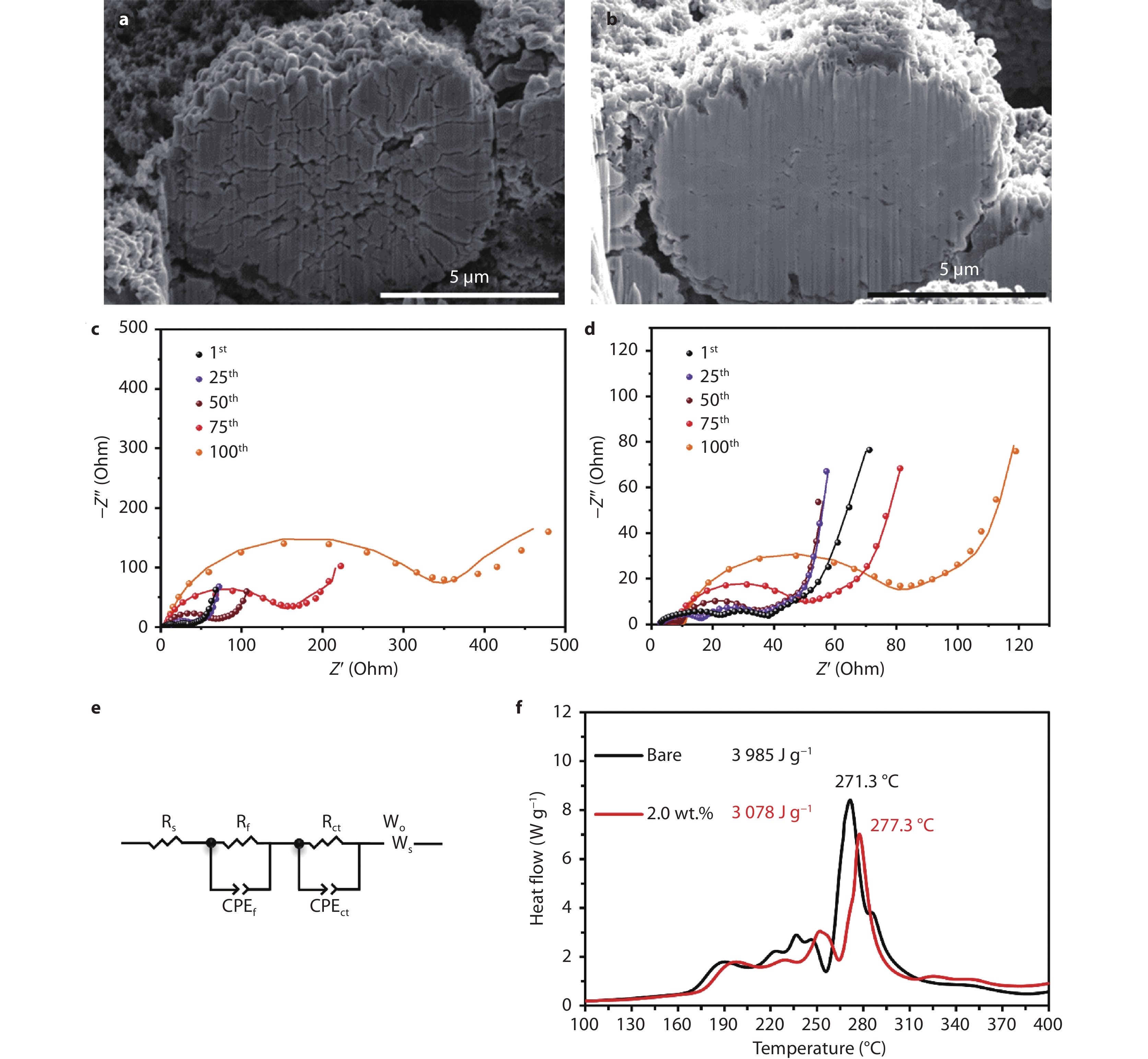

Figure 5.

The cross-sectional SEM images of single secondary particles from a bare and b 2.0 wt.% Al-modified NCM811 after 100 cycles at 1.0 C in the range of 2.7-4.3 V. The Nyquist plots of c bare and d 2.0 wt.% Al-modified NCM811 d after 100 cycles at 1.0 C in the range of 2.7-4.3 V, e DSC traces of bare and 2.0 wt.% Al-modified NCM811.

DownLoad:

DownLoad: