| Citation: | Hassina Tabassum, Shreya Mukherjee, Thomas O'Carroll, Tianjie Qiu, Xiaoxuan Yang, Ruqiang Zou, Gang Wu. High-entropy nanomaterials for electrochemical energy conversion and storage[J]. Energy Lab, 2023, 1(1): 220006. doi: 10.54227/elab.20220006 |

High-entropy nanomaterials for electrochemical energy conversion and storage

-

Abstract

High entropy materials (HEMs) with a single-phase structure have introduced a brand-new area of research in electrochemical energy conversion and storage devices. The fusion of divergent elements has been found to produce synergistic effects with advanced physicochemical phenomena. As such, heterometallic equiatomic proportion-based nanomaterials with stabilized configurational mixed entropy exhibit distinguished characteristics to enhance electrode catalytic activity and storage capability. This critical review summarizes the recent advances in developing HEMs at the nanoscale using different synthetic technologies. The most popular types of HEMs are high entropy alloys (HEAs) and high entropy oxides (HEOs), both of which present tunable structural properties. This review pays particular attention to recapitulating the necessary considerations to obtain HEAs effective for water splitting, fuel cell operation, CO2 reduction reactions, and energy storage applications. The demonstrated examples bestow a deep understanding of efficient HEM utilization as electrocatalysts and electrodes for charge storage devices. Finally, challenges and future perspectives pertaining to HEMs adoption as desirable materials for electrochemical energy conversion and storage devices will be discussed.

-

-

References

1. J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, S.-Y. Chang, Advanced Engineering Materials, 2004, 6, 299 2. T. A. A. Batchelor, J. K. Pedersen, S. H. Winther, I. E. Castelli, K. W. Jacobsen, J. Rossmeisl, Joule, 2019, 3, 834 3. B. E. MacDonald, Z. Fu, B. Zheng, W. Chen, Y. Lin, F. Chen, L. Zhang, J. Ivanisenko, Y. Zhou, H. Hahn, E. J. Lavernia, JOM, 2017, 69, 2024 4. L. Tao, M. Sun, Y. Zhou, M. Luo, F. Lv, M. Li, Q. Zhang, L. Gu, B. Huang, S. Guo, Journal of the American Chemical Society, 2022, 144, 10582 5. D. Zhang, H. Zhao, X. Wu, Y. Deng, Z. Wang, Y. Han, H. Li, Y. Shi, X. Chen, S. Li, J. Lai, B. Huang, L. Wang, Advanced Functional Materials, 2021, 31, 2006939 6. A. Amiri, R. Shahbazian-Yassar, Journal of Materials Chemistry A, 2021, 9, 782 7. Y. Cui, Y. Zhang, Z. Cao, J. Gu, Z. Du, B. Li, S. Yang, SusMat, 2022, 2, 65 8. H. Liu, L. Syama, L. Zhang, C. Lee, C. Liu, Z. Dai, Q. Yan, SusMat, 2021, 1, 482 9. J. K. Nørskov, J. Rossmeisl, A. Logadottir, L. Lindqvist, J. R. Kitchin, T. Bligaard, H. Jónsson, The Journal of Physical Chemistry B, 2004, 108, 17886 10. C. M. Rost, E. Sachet, T. Borman, A. Moballegh, E. C. Dickey, D. Hou, J. L. Jones, S. Curtarolo, J. P. Maria, Nature Communications, 2015, 6, 8485 11. D. Raabe, C. C. Tasan, H. Springer, M. Bausch, Steel Research International, 2015, 86, 1127 12. C.-J. Tong, Y.-L. Chen, J.-W. Yeh, S.-J. Lin, S.-K. Chen, T.-T. Shun, C.-H. Tsau, S.-Y. Chang, Metallurgical and Materials Transactions A, 2005, 36, 881 13. X. Cui, B. Zhang, C. Zeng, S. Guo, MRS Communications, 2018, 8, 1230 14. R. M. Arán-Ais, F. Dionigi, T. Merzdorf, M. Gocyla, M. Heggen, R. E. Dunin-Borkowski, M. Gliech, J. Solla-Gullón, E. Herrero, J. M. Feliu, P. Strasser, Nano Letters, 2015, 15, 7473 15. E. P. George, W. A. Curtin, C. C. Tasan, Acta Materialia, 2020, 188, 435 16. B. Cantor, I. T. H. Chang, P. Knight, A. J. B. Vincent, Materials Science and Engineering: A, 2004, 375−377,213 17. K. B. Kim, Y. Zhang, P. J. Warren, B. Cantor, Philosophical Magazine, 2003, 83, 2371 18. B. Cantor, Entropy, 2014, 16, 4749 19. J. W. Yeh, Annales de Chimie Science des Materiaux (Paris), 2006, 31, 633 20. J. W. Yeh, Y. L. Chen, S. J. Lin, S. K. Chen, Materials Science Forum, 2007, 560, 1 21. C.-J. Tong, M.-R. Chen, J.-W. Yeh, S.-J. Lin, S.-K. Chen, T.-T. Shun, S.-Y. Chang, Metallurgical and Materials Transactions A, 2005, 36, 1263 22. S. Ranganathan, In Alloyed pleasures: Multimetallic cocktails, 2003 23. L. J. Santodonato, Y. Zhang, M. Feygenson, C. M. Parish, M. C. Gao, R. J. K. Weber, J. C. Neuefeind, Z. Tang, P. K. Liaw, Nature Communications, 2015, 6, 5964 24. P. Poizot, S. Laruelle, S. Grugeon, L. Dupont, J. M. Tarascon, Nature, 2000, 407, 496 25. Y. F. Ye, Q. Wang, J. Lu, C. T. Liu, Y. Yang, Scripta Materialia, 2015, 104, 53 26. Y. Zhang, T. T. Zuo, Z. Tang, M. C. Gao, K. A. Dahmen, P. K. Liaw, Z. P. Lu, Progress in Materials Science, 2014, 61, 1 27. M. C. Gao, JOM, 2015, 67, 2251 28. R. A. Swalin, American Journal of Physics, 1962, 30, 778 29. Y. F. Ye, Q. Wang, J. Lu, C. T. Liu, Y. Yang, Intermetallics, 2015, 59, 75 30. Y. F. Ye, Q. Wang, J. Lu, C. T. Liu, Y. Yang, Materials Today, 2016, 19, 349 31. U. Mizutani, MRS Bulletin, 2012, 37, 169 32. S. Guo, C. Ng, J. Lu, C. T. Liu, Journal of Applied Physics, 2011, 109, 103505 33. S. Guo, C. Ng, C. T. Liu, Journal of Alloys and Compounds, 2013, 557, 77 34. M. G. Poletti, L. Battezzati, Acta Materialia, 2014, 75, 297 35. H. Y. Ding, K. F. Yao, Journal of Non-Crystalline Solids, 2013, 364, 9 36. O. N. Senkov, J. D. Miller, D. B. Miracle, C. Woodward, Nature Communications, 2015, 6, 6529 37. Y. Zou, H. Ma, R. Spolenak, Nature Communications, 2015, 6, 7748 38. O. N. Senkov, G. B. Wilks, D. B. Miracle, C. P. Chuang, P. K. Liaw, Intermetallics, 2010, 18, 1758 39. A. Takeuchi, K. Amiya, T. Wada, K. Yubuta, W. Zhang, JOM, 2014, 66, 1984 40. G. A. Mansoori, N. F. Carnahan, K. E. Starling, T. W. Leland Jr, The Journal of Chemical Physics, 1971, 54, 1523 41. X. Yang, Y. Zhang, Materials Chemistry and Physics, 2012, 132, 233 42. J.-W. Yeh, S.-Y. Chang, Y.-D. Hong, S.-K. Chen, S.-J. Lin, Materials Chemistry and Physics, 2007, 103, 41 43. L. Liu, J. B. Zhu, L. Li, J. C. Li, Q. Jiang, Materials & Design, 2013, 44, 223 44. Y. Zhang, Z. P. Lu, S. G. Ma, P. K. Liaw, Z. Tang, Y. Q. Cheng, M. C. Gao, MRS Communications, 2014, 4, 57 45. M. J. Yao, K. G. Pradeep, C. C. Tasan, D. Raabe, Scripta Materialia, 2014, 72−73, 5 46. Y. Deng, C. C. Tasan, K. G. Pradeep, H. Springer, A. Kostka, D. Raabe, Acta Materialia, 2015, 94, 124 47. O. N. Senkov, S. V. Senkova, C. Woodward, D. B. Miracle, Acta Materialia, 2013, 61, 1545 48. N. D. Stepanov, D. G. Shaysultanov, G. A. Salishchev, M. A. Tikhonovsky, Materials Letters, 2015, 142, 153 49. K. Lu, Science, 2014, 345, 1455 50. K. Lu, L. Lu, S. Suresh, Science, 2009, 324, 349 51. H. Kou, J. Lu, Y. Li, Advanced Materials, 2014, 26, 5518 52. P. L. Sun, Y. H. Zhao, T. Y. Tseng, J. R. Su, E. J. Lavernia, Materials Science and Engineering: A, 2010, 527, 5287 53. A. J. Zaddach, C. Niu, C. C. Koch, D. L. Irving, JOM, 2013, 65, 1780 54. Y. L. Gong, C. E. Wen, Y. C. Li, X. X. Wu, L. P. Cheng, X. C. Han, X. K. Zhu, Materials Science and Engineering: A, 2013, 569, 144 55. F. Otto, Y. Yang, H. Bei, E. P. George, Acta Materialia, 2013, 61, 2628 56. S. Guo, C. T. Liu, Progress in Natural Science:Materials International, 2011, 21, 433 57. F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler, E. P. George, Acta Materialia, 2013, 61, 5743 58. T. Löffler, H. Meyer, A. Savan, P. Wilde, A. Garzón Manjón, Y.-T. Chen, E. Ventosa, C. Scheu, A. Ludwig, W. Schuhmann, Advanced Energy Materials, 2018, 8, 1802269 59. H. Meyer, M. Meischein, A. Ludwig, ACS Combinatorial Science, 2018, 20, 243 60. M. Schwartzkopf, G. Santoro, C. J. Brett, A. Rothkirch, O. Polonskyi, A. Hinz, E. Metwalli, Y. Yao, T. Strunskus, F. Faupel, P. Müller-Buschbaum, S. V. Roth, ACS Applied Materials & Interfaces, 2015, 7, 13547 61. M. Meischein, A. Garzón-Manjón, T. Frohn, H. Meyer, S. Salomon, C. Scheu, A. Ludwig, ACS Combinatorial Science, 2019, 21, 743 62. M. T. Nguyen, T. Yonezawa, Science and Technology of Advanced Materials, 2018, 19, 883 63. D. Sugioka, T. Kameyama, S. Kuwabata, T. Yamamoto, T. Torimoto, ACS Applied Materials & Interfaces, 2016, 8, 10874 64. D. König, K. Richter, A. Siegel, A.-V. Mudring, A. Ludwig, Advanced Functional Materials, 2014, 24, 2049 65. Y. Zhang, X. Yan, J. Ma, Z. Lu, Y. Zhao, Journal of Materials Research, 2018, 33, 3330 66. S. Reichenberger, G. Marzun, M. Muhler, S. Barcikowski, ChemCatChem, 2019, 11, 4489 67. F. Waag, Y. Li, A. R. Ziefuß, E. Bertin, M. Kamp, V. Duppel, G. Marzun, L. Kienle, S. Barcikowski, B. Gökce, RSC Advances, 2019, 9, 18547 68. Y. Yao, Q. Dong, L. Hu, Matter, 2019, 1, 1451 69. Y. Yao, Z. Huang, P. Xie, L. Wu, L. Ma, T. Li, Z. Pang, M. Jiao, Z. Liang, J. Gao, Y. He, D. J. Kline, M. R. Zachariah, C. Wang, J. Lu, T. Wu, T. Li, C. Wang, R. Shahbazian-Yassar, L. Hu, Nature Nanotechnology, 2019, 14, 851 70. S. Gao, S. Hao, Z. Huang, Y. Yuan, S. Han, L. Lei, X. Zhang, R. Shahbazian-Yassar, J. Lu, Nature Communications, 2020, 11, 2016 71. Y. Yao, Z. Huang, P. Xie, S. D. Lacey, R. J. Jacob, H. Xie, F. Chen, A. Nie, T. Pu, M. Rehwoldt, D. Yu, M. R. Zachariah, C. Wang, R. Shahbazian-Yassar, J. Li, L. Hu, Science, 2018, 359, 1489 72. P. Xie, Y. Yao, Z. Huang, Z. Liu, J. Zhang, T. Li, G. Wang, R. Shahbazian-Yassar, L. Hu, C. Wang, Nature Communications, 2019, 10, 4011 73. Z. Peng, H. Yang, Nano Today, 2009, 4, 143 74. Y. Li, Y. Liao, J. Zhang, E. Huang, L. Ji, Z. Zhang, R. Zhao, Z. Zhang, B. Yang, Y. Zhang, B. Xu, G. Qin, X. Zhang, Angewandte Chemie International Edition, 2021, 60, 27113 75. W. Shi, H. Liu, Z. Li, C. Li, J. Zhou, Y. Yuan, F. Jiang, K. Fu, Y. Yao, SusMat, 2022, 2, 186 76. T. Löffler, A. Ludwig, J. Rossmeisl, W. Schuhmann, Angewandte Chemie International Edition, 2021, 60, 26894 77. M. W. Glasscott, J. E. Dick, Analytical Chemistry, 2018, 90, 7804 78. J. E. Dick, E. Lebègue, L. M. Strawsine, A. J. Bard, Electroanalysis, 2016, 28, 2320 79. J. E. Dick, C. Renault, B.-K. Kim, A. J. Bard, Angewandte Chemie International Edition, 2014, 53, 11859 80. X. Huang, G. Yang, S. Li, H. Wang, Y. Cao, F. Peng, H. Yu, Journal of Energy Chemistry, 2022, 68, 721 81. B. Wang, Y. Yao, X. Yu, C. Wang, C. Wu, Z. Zou, Journal of Materials Chemistry A, 2021, 9, 19410 82. M. W. Glasscott, A. D. Pendergast, S. Goines, A. R. Bishop, A. T. Hoang, C. Renault, J. E. Dick, Nature Communications, 2019, 10, 2650 83. B. Niu, F. Zhang, H. Ping, N. Li, J. Zhou, L. Lei, J. Xie, J. Zhang, W. Wang, Z. Fu, Scientific Reports, 2017, 7, 3421 84. F. Okejiri, Z. Zhang, J. Liu, M. Liu, S. Yang, S. Dai, ChemSusChem, 2020, 13, 111 85. K. Gu, D. Wang, C. Xie, T. Wang, G. Huang, Y. Liu, Y. Zou, L. Tao, S. Wang, Angewandte Chemie International Edition, 2021, 60, 20253 86. P.-C. Chen, M. Liu, J. S. Du, B. Meckes, S. Wang, H. Lin, V. P. Dravid, C. Wolverton, C. A. Mirkin, Science, 2019, 363, 959 87. D. Zhang, Y. Shi, H. Zhao, W. Qi, X. Chen, T. Zhan, S. Li, B. Yang, M. Sun, J. Lai, B. Huang, L. Wang, Journal of Materials Chemistry A, 2021, 9, 889 88. C. Zhan, Y. Xu, L. Bu, H. Zhu, Y. Feng, T. Yang, Y. Zhang, Z. Yang, B. Huang, Q. Shao, X. Huang, Nature Communications, 2021, 12, 6261 89. N. K. Katiyar, S. Nellaiappan, R. Kumar, K. D. Malviya, K. G. Pradeep, A. K. Singh, S. Sharma, C. S. Tiwary, K. Biswas, Materials Today Energy, 2020, 16, 100393 90. H. Tabassum, R. Zou, A. Mahmood, Z. Liang, S. Guo, Journal of Materials Chemistry A, 2016, 4, 16469 91. V. Tripkovic, H. A. Hansen, J. Rossmeisl, T. Vegge, Physical Chemistry Chemical Physics, 2015, 17, 11647 92. T. Löffler, A. Savan, H. Meyer, M. Meischein, V. Strotkötter, A. Ludwig, W. Schuhmann, Angewandte Chemie International Edition, 2020, 59, 5844 93. K. D. Jensen, J. Tymoczko, J. Rossmeisl, A. S. Bandarenka, I. Chorkendorff, M. Escudero-Escribano, I. E. L. Stephens, Angewandte Chemie International Edition, 2018, 57, 2800 94. X. Ji, P. Gao, L. Zhang, X. Wang, F. Wang, H. Zhu, J. Yu, ChemElectroChem, 2019, 6, 3065 95. Y. Yao, Z. Huang, T. Li, H. Wang, Y. Liu, H. S. Stein, Y. Mao, J. Gao, M. Jiao, Q. Dong, J. Dai, P. Xie, H. Xie, S. D. Lacey, I. Takeuchi, J. M. Gregoire, R. Jiang, C. Wang, A. D. Taylor, R. Shahbazian-Yassar, L. Hu, Proc. Natl. Acad. Sci. U. S. A., 2020, 117, 6316 96. S. Li, X. Tang, H. Jia, H. Li, G. Xie, X. Liu, X. Lin, H.-J. Qiu, Journal of Catalysis, 2020, 383, 164 97. A. Sarkar, A. Vadivel Murugan, A. Manthiram, Fuel Cells, 2010, 10, 375 98. H. Li, Y. Han, H. Zhao, W. Qi, D. Zhang, Y. Yu, W. Cai, S. Li, J. Lai, B. Huang, L. Wang, Nature Communications, 2020, 11, 5437 99. J. K. Pedersen, C. M. Clausen, O. A. Krysiak, B. Xiao, T. A. A. Batchelor, T. Löffler, V. A. Mints, L. Banko, M. Arenz, A. Savan, W. Schuhmann, A. Ludwig, J. Rossmeisl, Angewandte Chemie International Edition, 2021, 60, 24144 100. W. Dai, T. Lu, Y. Pan, Journal of Power Sources, 2019, 430, 104 101. Z. Ding, J. Bian, S. Shuang, X. Liu, Y. Hu, C. Sun, Y. Yang, Advanced Sustainable Systems, 2020, 4, 1900105 102. D. Wang, Z. Liu, S. Du, Y. Zhang, H. Li, Z. Xiao, W. Chen, R. Chen, Y. Wang, Y. Zou, S. Wang, Journal of Materials Chemistry A, 2019, 7, 24211 103. H.-J. Qiu, G. Fang, J. Gao, Y. Wen, J. Lv, H. Li, G. Xie, X. Liu, S. Sun, ACS Materials Letters, 2019, 1, 526 104. X. Zhao, Z. Xue, W. Chen, X. Bai, R. Shi, T. Mu, Journal of Materials Chemistry A, 2019, 7, 26238 105. M. Liu, Z. Zhang, F. Okejiri, S. Yang, S. Zhou, S. Dai, Advanced Materials Interfaces, 2019, 6, 1900015 106. H. Tabassum, W. Guo, W. Meng, A. Mahmood, R. Zhao, Q. Wang, R. Zou, Advanced Energy Materials, 2017, 7, 1601671 107. G. Zhang, K. Ming, J. Kang, Q. Huang, Z. Zhang, X. Zheng, X. Bi, Electrochimica Acta, 2018, 279, 19 108. G. Fang, J. Gao, J. Lv, H. Jia, H. Li, W. Liu, G. Xie, Z. Chen, Y. Huang, Q. Yuan, X. Liu, X. Lin, S. Sun, H.-J. Qiu, Applied Catalysis B:Environmental, 2020, 268, 118431 109. P. Edalati, Q. Wang, H. Razavi-Khosroshahi, M. Fuji, T. Ishihara, K. Edalati, Journal of Materials Chemistry A, 2020, 8, 3814 110. H.-J. Qiu, G. Fang, Y. Wen, P. Liu, G. Xie, X. Liu, S. Sun, Journal of Materials Chemistry A, 2019, 7, 6499 111. A. Sahasrabudhe, H. Dixit, R. Majee, S. Bhattacharyya, Nature Communications, 2018, 9, 2014 112. S. D. Lacey, Q. Dong, Z. Huang, J. Luo, H. Xie, Z. Lin, D. J. Kirsch, V. Vattipalli, C. Povinelli, W. Fan, R. Shahbazian-Yassar, D. Wang, L. Hu, Nano Letters, 2019, 19, 5149 113. Z. Jin, J. Lv, H. Jia, W. Liu, H. Li, Z. Chen, X. Lin, G. Xie, X. Liu, S. Sun, H.-J. Qiu, Small, 2019, 15, 1904180 114. H. Tabassum, X. Yang, R. Zou, G. Wu, Chem Catalysis, 2022, 2, 1561 115. Y. Li, W. Shan, M. J. Zachman, M. Wang, S. Hwang, H. Tabassum, J. Yang, X. Yang, S. Karakalos, Z. Feng, G. Wang, G. Wu, Angewandte Chemie International Edition, 2022, 61, e202205632 116. S. Nellaiappan, N. K. Katiyar, R. Kumar, A. Parui, K. D. Malviya, K. G. Pradeep, A. K. Singh, S. Sharma, C. S. Tiwary, K. Biswas, ACS Catalysis, 2020, 10, 3658 117. H. Tabassum, S. Mukherjee, J. Chen, D. Holiharimanana, S. Karakalos, X. Yang, S. Hwang, T. Zhang, B. Lu, M. Chen, Z. Tang, E. A. Kyriakidou, Q. Ge, G. Wu, Energy & Environmental Science, 2022, 15, 4190 118. L. Spiridigliozzi, C. Ferone, R. Cioffi, G. Accardo, D. Frattini, G. Dell'Agli, Materials (Basel), 2020, 13, 558 119. A. Sarkar, Q. Wang, A. Schiele, M. R. Chellali, S. S. Bhattacharya, D. Wang, T. Brezesinski, H. Hahn, L. Velasco, B. Breitung, Advanced Materials, 2019, 31, 1806236 120. D. A. Vinnik, E. A. Trofimov, V. E. Zhivulin, S. A. Gudkova, O. V. Zaitseva, D. A. Zherebtsov, A. Y. Starikov, D. P. Sherstyuk, A. A. Amirov, A. V. Kalgin, S. V. Trukhanov, F. V. Podgornov, Nanomaterials (Basel), 2020, 10, 268 121. M. Lim, Z. Rak, J. L. Braun, C. M. Rost, G. N. Kotsonis, P. E. Hopkins, J.-P. Maria, D. W. Brenner, Journal of Applied Physics, 2019, 125, 055105 122. A. Sarkar, L. Velasco, D. Wang, Q. Wang, G. Talasila, L. de Biasi, C. Kübel, T. Brezesinski, S. S. Bhattacharya, H. Hahn, B. Breitung, Nature Communications, 2018, 9, 3400 123. R. Djenadic, A. Sarkar, O. Clemens, C. Loho, M. Botros, V. S. K. Chakravadhanula, C. Kübel, S. S. Bhattacharya, A. S. Gandhi, H. Hahn, Materials Research Letters, 2017, 5, 102 124. H. Chen, J. Fu, P. Zhang, H. Peng, C. W. Abney, K. Jie, X. Liu, M. Chi, S. Dai, Journal of Materials Chemistry A, 2018, 6, 11129 125. A. Sarkar, C. Loho, L. Velasco, T. Thomas, S. S. Bhattacharya, H. Hahn, R. Djenadic, Dalton Transactions, 2017, 46, 12167 126. K. Walczak, A. Plewa, C. Ghica, W. Zając, A. Trenczek-Zając, M. Zając, J. Toboła, J. Molenda, Energy Storage Materials, 2022, 47, 500 127. J. Dąbrowa, M. Stygar, A. Mikuła, A. Knapik, K. Mroczka, W. Tejchman, M. Danielewski, M. Martin, Materials Letters, 2018, 216, 32 128. W. Hong, F. Chen, Q. Shen, Y.-H. Han, W. G. Fahrenholtz, L. Zhang, Journal of the American Ceramic Society, 2019, 102, 2228 129. H. Tabassum, C. Zhi, T. Hussain, T. Qiu, W. Aftab, R. Zou, Advanced Energy Materials, 2019, 9, 1901778 130. H. Tabassum, C. Zhi, Y. Wu, R. Zhong, T. Hussain, T. Qiu, Y. Tang, Z. Liang, W. Guo, R. Zou, Chemical Engineering Journal, 2021, 411, 128420 131. H. Tabassum, R. Zou, A. Mahmood, Z. Liang, Q. Wang, H. Zhang, S. Gao, C. Qu, W. Guo, S. Guo, Advanced materials, 2018, 30, 1705441 132. A. Mahmood, S. Li, Z. Ali, H. Tabassum, B. Zhu, Z. Liang, W. Meng, W. Aftab, W. Guo, H. Zhang, M. Yousaf, S. Gao, R. Zou, Y. Zhao, Advanced Materials, 2019, 31, 1805430 133. C. Zhao, F. Ding, Y. Lu, L. Chen, Y. S. Hu, Angewandte Chemie International Edition, 2020, 59, 264 134. D. Bérardan, S. Franger, A. K. Meena, N. Dragoe, Journal of Materials Chemistry A, 2016, 4, 9536 135. A. Sarkar, R. Djenadic, N. J. Usharani, K. P. Sanghvi, V. S. K. Chakravadhanula, A. S. Gandhi, H. Hahn, S. S. Bhattacharya, Journal of the European Ceramic Society, 2017, 37, 747 136. X. Wang, X. Li, H. Fan, M. Miao, Y. Zhang, W. Guo, Y. Fu, Journal of Energy Chemistry, 2022, 67, 276 137. L. Lin, K. Wang, A. Sarkar, C. Njel, G. Karkera, Q. Wang, R. Azmi, M. Fichtner, H. Hahn, S. Schweidler, B. Breitung, Advanced Energy Materials, 2022, 12, 2103090 138. H. Li, H. Zhu, S. Zhang, N. Zhang, M. Du, Y. Chai, Small Structures, 2020, 1, 2000033 139. X. Liu, X. Li, Y. Li, H. Zhang, Q. Jia, S. Zhang, W. Lei, EcoMat, 2022, e12261 140. H. Tabassum, C. Qu, K. Cai, W. Aftab, Z. Liang, T. Qiu, A. Mahmood, W. Meng, R. Zou, Journal of Materials Chemistry A, 2018, 6, 21225 141. X. Xu, Y. Du, C. Wang, Y. Guo, J. Zou, K. Zhou, Z. Zeng, Y. Liu, L. Li, Journal of Alloys and Compounds, 2020, 822, 153642 142. K. Kong, J. Hyun, Y. Kim, W. Kim, D. Kim, Journal of Power Sources, 2019, 437, 226927 143. M. S. Lal, R. Sundara, ACS applied materials & interfaces, 2019, 11, 30846 -

Rights and permissions

This is an open access article under the terms of the Creative Commons Attribution License, which permits use, distribution and reproduction in any medium, provided the original work is properly cited.

Information

Article Metrics

-

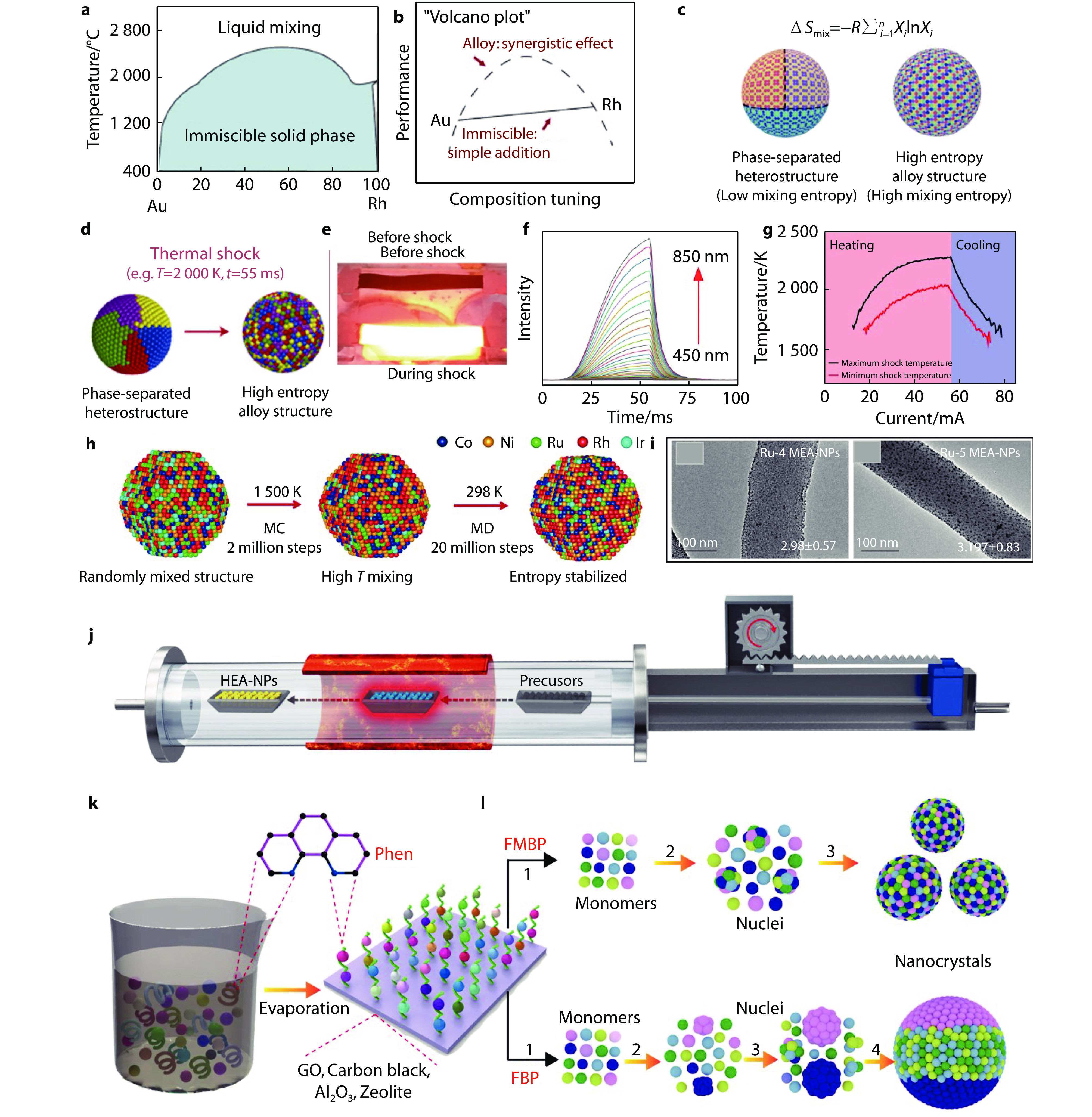

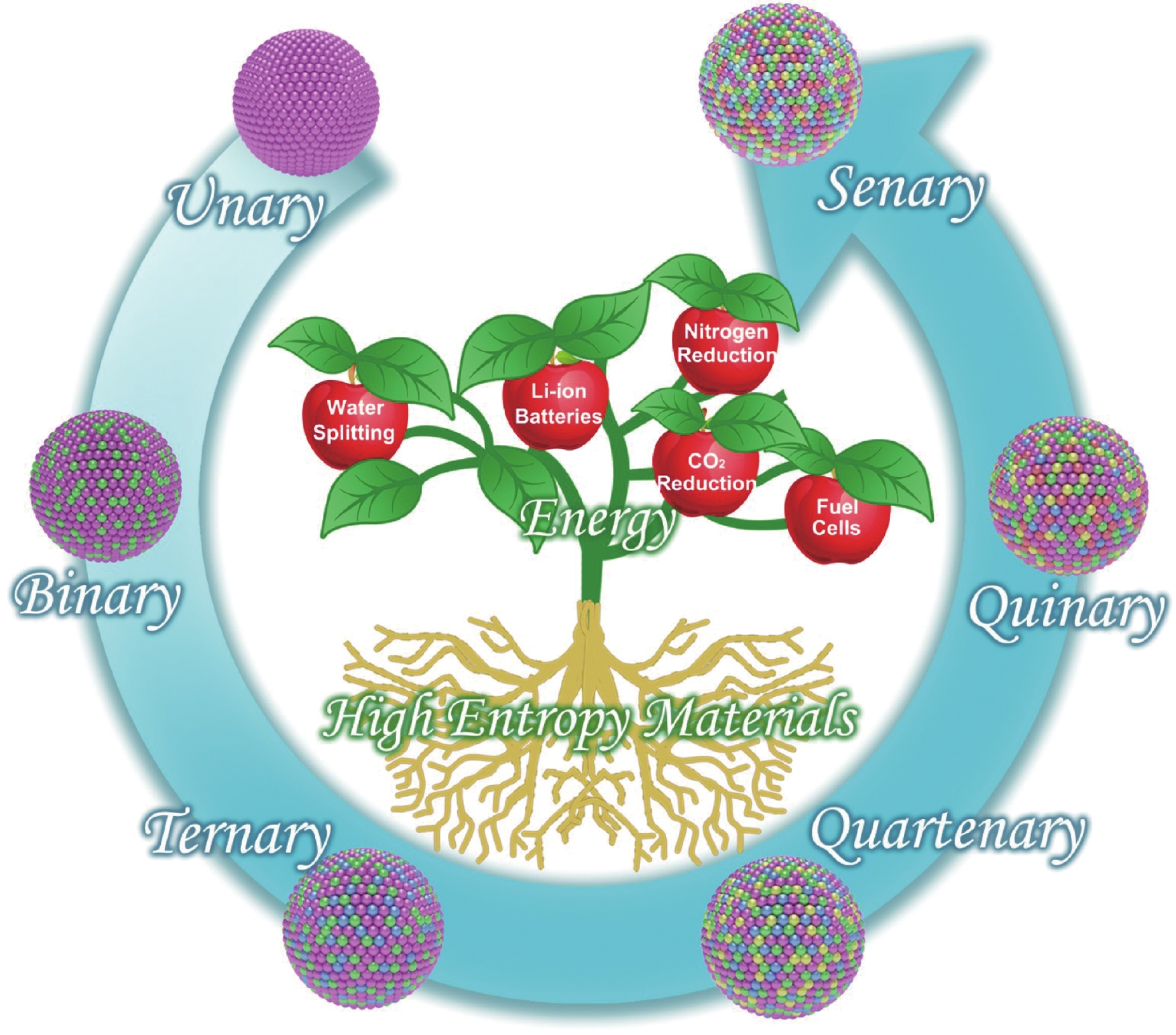

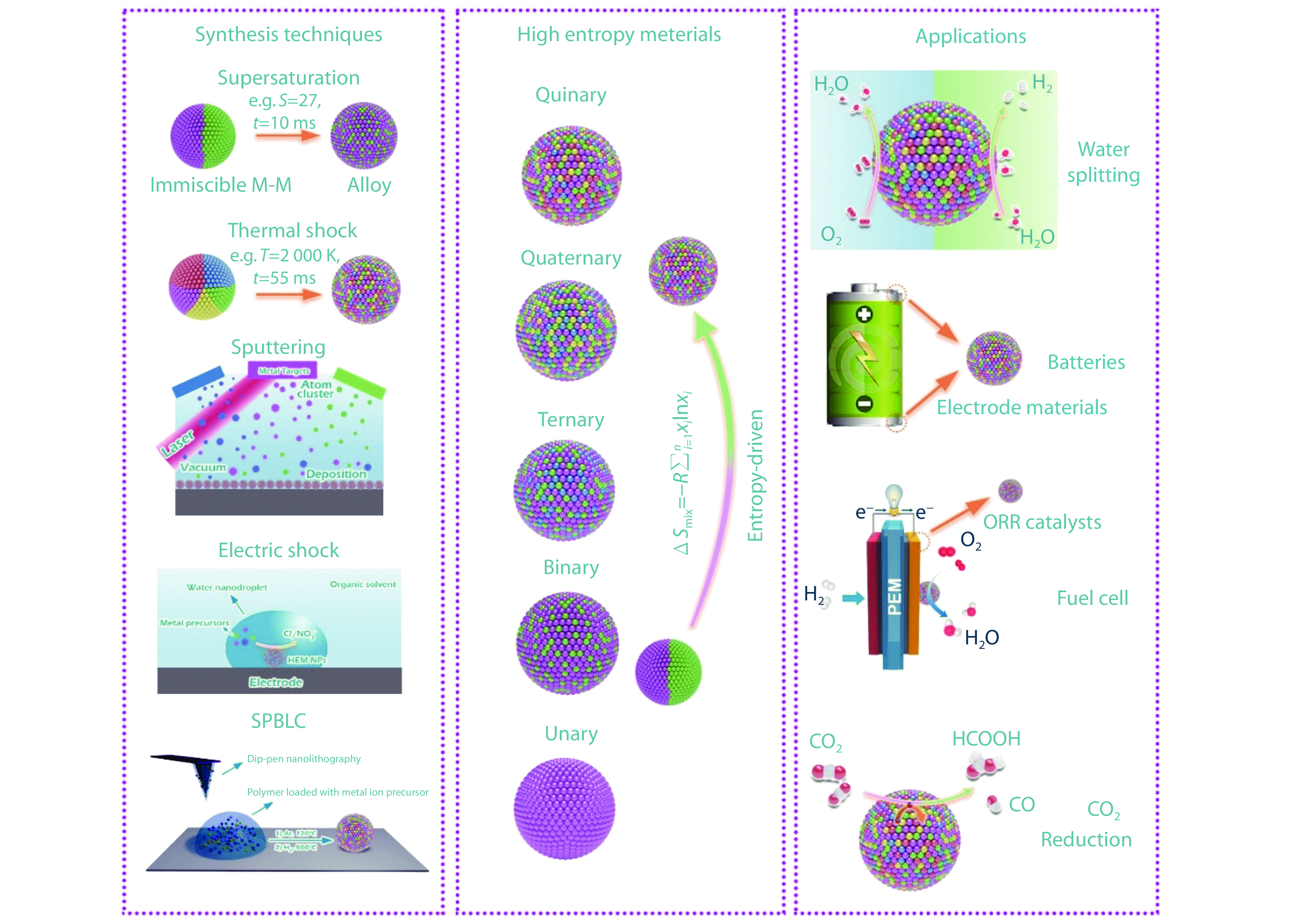

Figure 1.

Schematic illustration for the fabrication techniques of HEMs and Electrochemical properties.

-

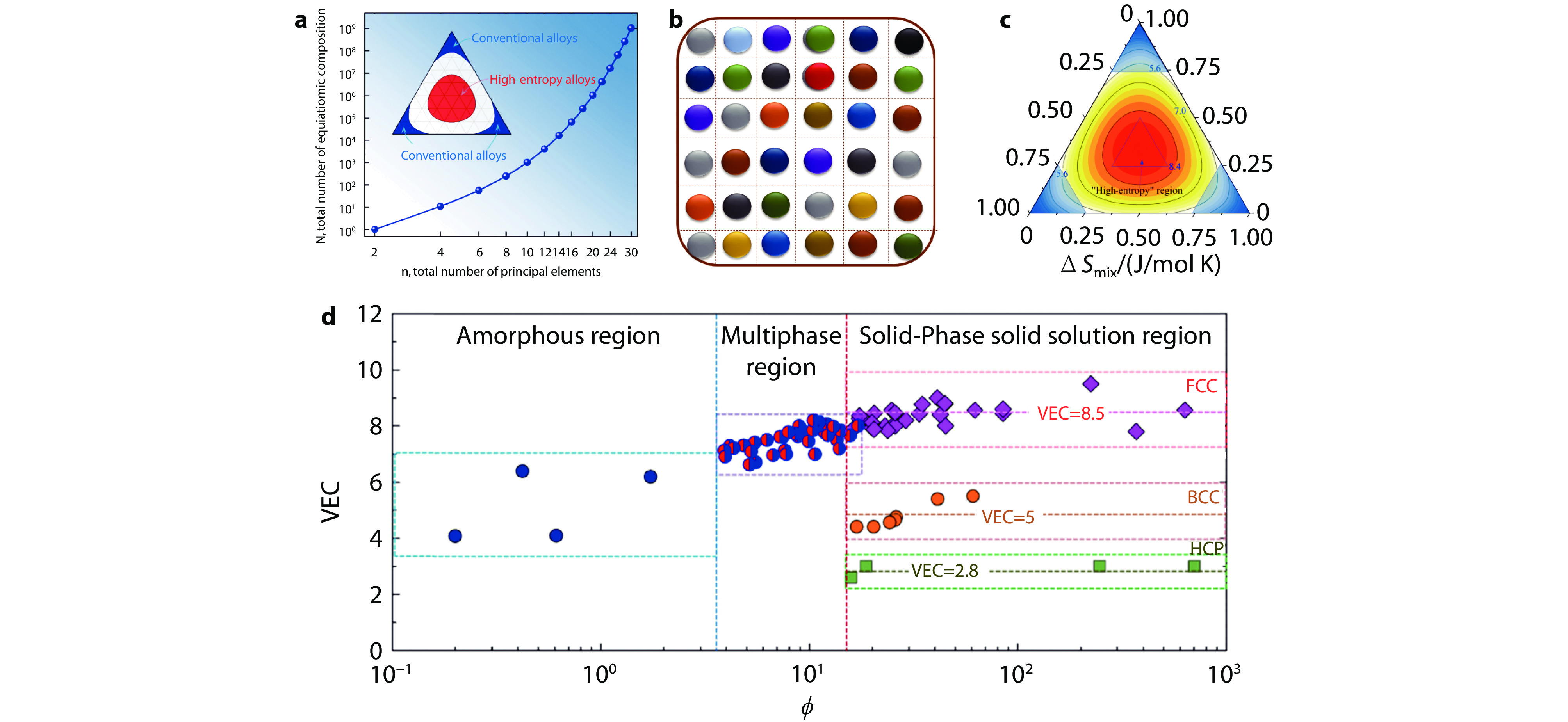

Figure 2.

a The variation in the total number of equiatomic compositions with the total number of principal elements. The inset illustrates the difference between the design of conventional alloys and high-entropy alloys on a ternary plot.[1] Copyright 2018, Elsevier. b Schematics of the atomic configuration of a multi-component alloy conforming to the ideal-solution model.[29] Copyright 2015, Elsevier. c The contour plot of ΔSmix (J/mol K) on a schematic ternary alloy system. The blue corner regions indicate the conventional alloys based on one or two principal elements, whereas the red center region indicates the ‘high-entropy’ region.[30] Copyright 2016, Elsevier. d The plot of the VEC versus ϕ for different HEAs. The FCC solid solution mainly forms around a VEC of 8.5, BCC around a VEC of 5, and HCP around a VEC of 2.8, each within a narrow band.[30] Copyright 2016, Elsevier.

-

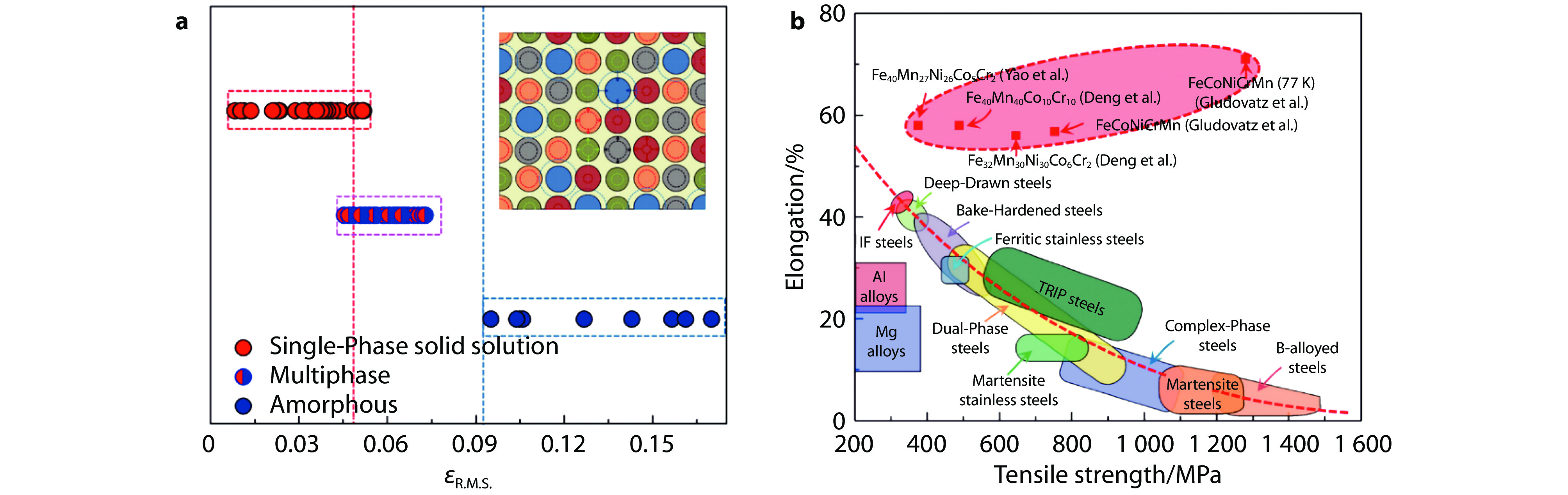

Figure 3.

a The groupings of different-phased HEAs based on their intrinsic root-mean-square (RMS) residual strains. The inset illustrates the atomic size alteration to accommodate close atomic packing atoms in the lattice of a multicomponent alloy, and the dashed cycles indicate the original atomic size.[30] Copyright 2016, Elsevier. b Strength versus ductility properties for low-SFE HEAs such as Fe40Mn27Ni26Co5Cr[45, 46] Fe32Mn30Ni30Co6Cr2, and FeCoNiCrMn are at room temperature and FeCoNiCrMn at 77 K, compared with other conventional alloys.[30] Copyright 2016, Elsevier.

-

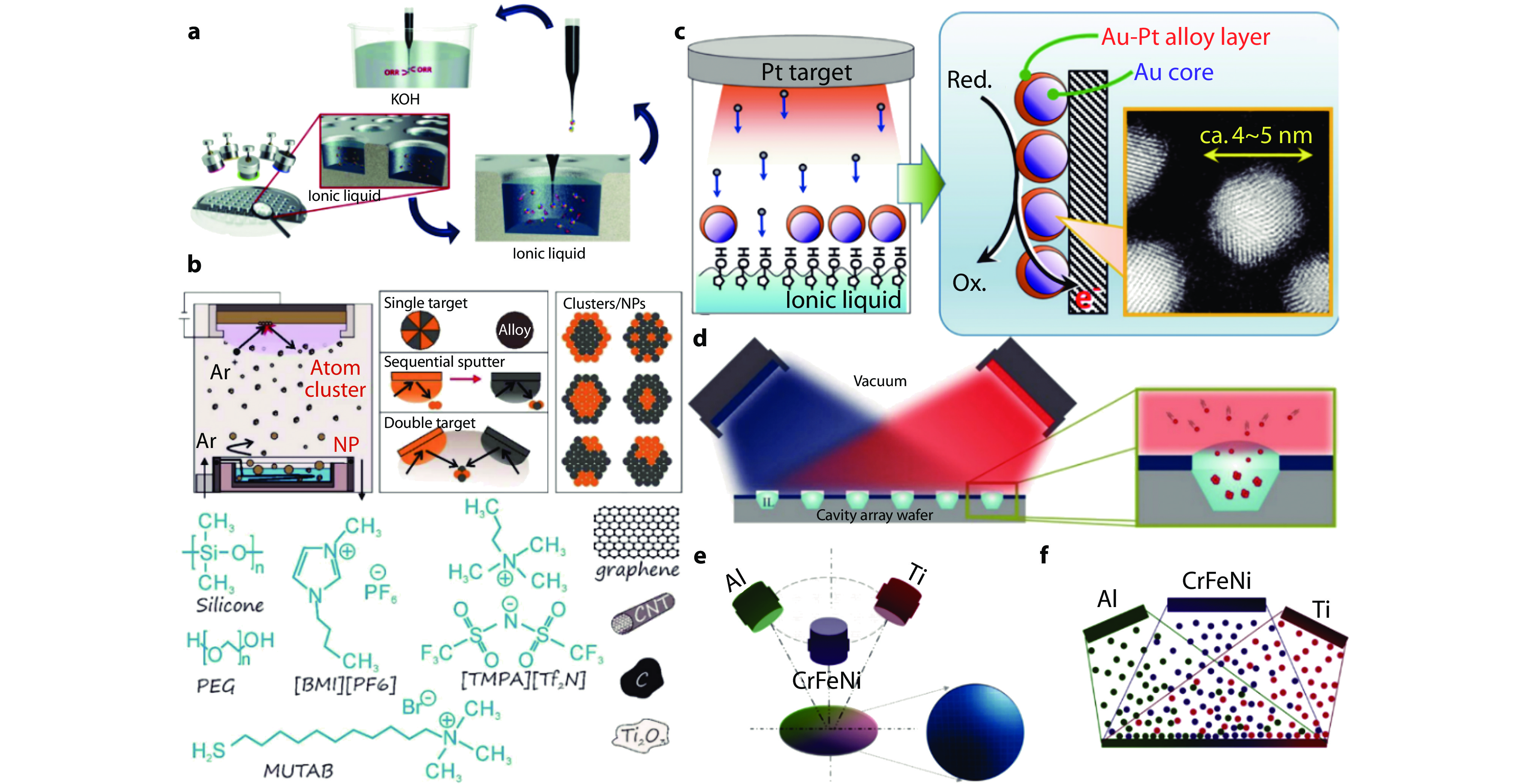

Figure 4.

a Strategy for evaluation of the intrinsic activity of multinary alloy NPs. synthesis of NPs by means of combinatorial co-sputtering into an ionic liquid under potential-assisted immobilization at an etched carbon.[58] Copyright 2013, Wiley-VCH. b Vacuum sputtering onto different liquids for obtaining bimetallic/trimetallic NPs/NCs with desired fine structures.[62] Copyrights 2018, Iopscience. c Upper left: schematic (not to scale) of the combinatorial co-deposition from two sputter targets into a cavity array substrate filled with IL. Upper right: Schematic of the proposed formation process of NPs in IL. Lower left: photo EDX screening for the four materials libraries.[63] Copyright 2016, American Chemical Society. d Sequential sputtering of Au followed by Pt to form a monolayer of Au core@Au/Pt alloy shell NPs functionalized on IL.[64] Copyright 2013, Wiley-VCH. e Schematic diagram of multitarget co-sputtering: three-dimensional view co-sputtering and f front view and the process of deposition.[65] Copyright 2018, Materials Research Society.

-

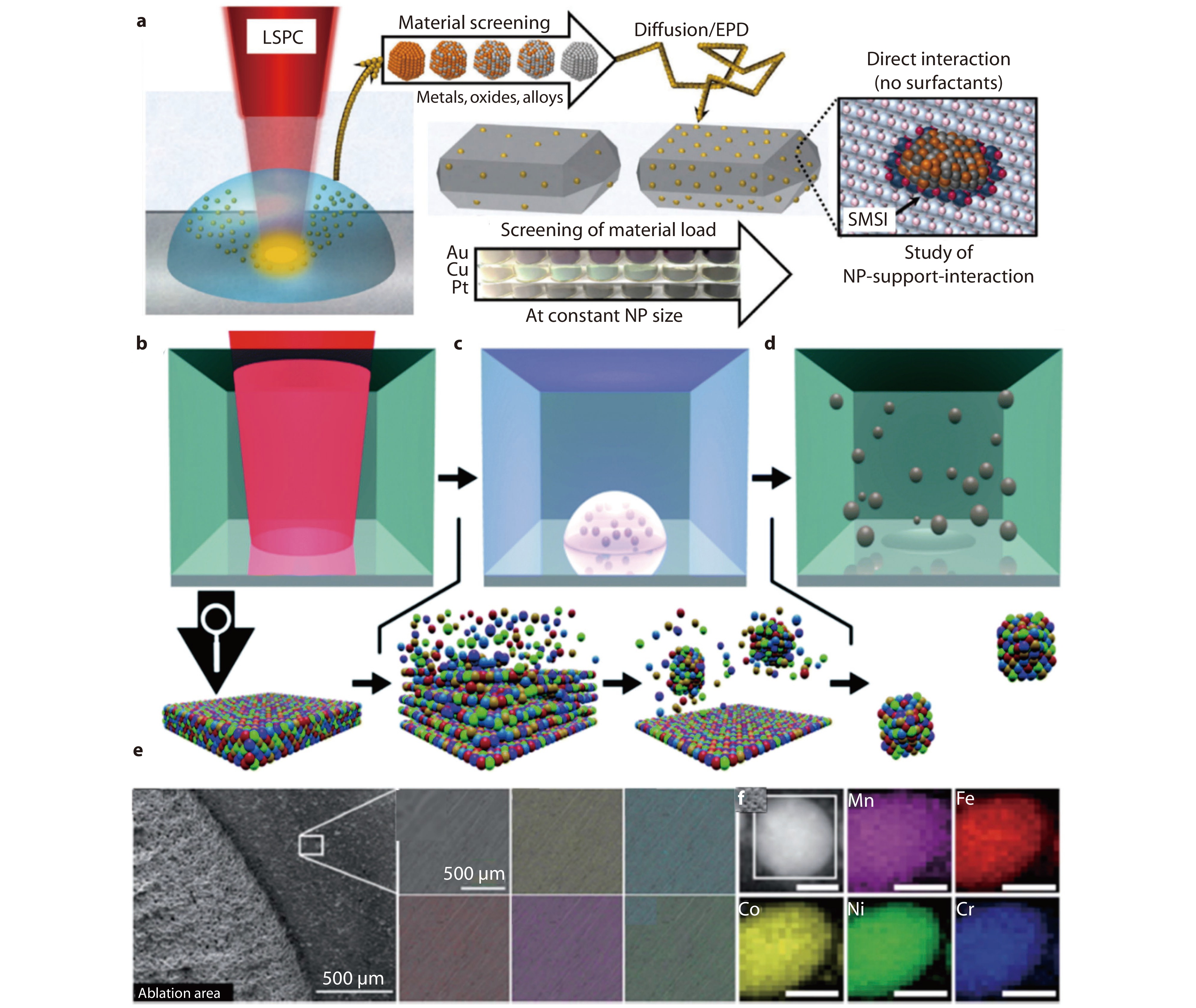

Figure 5.

a General strategy of Laser Synthesis and Processing of Colloids (LSPC) in research on heterogeneous catalysis.[66] Copyright 2013, Wiley-VCH. b Qualitative representation of the laser-based synthesis of high-entropy alloy nanoparticles. Synthetic stages c ultrashort-pulsed laser irradiation of the bulk high-entropy alloy (HEA), the atomization/ionization of the bulk causing the formation of a plume, and subsequent nucleation and condensation of the ablated matter in the vapor phase of the liquid d and the colloidal high-entropy alloy nanoparticles electrostatically stabilized in ethanol. e Scanning electron microscope image (secondary electrons) of an ablation target near the border of an ablation area, elemental maps of Co, Cr, Fe, Mn, and Ni obtained by energy dispersive X-ray spectroscopy of a non-ablated target area f and scanning transmission electron microscopy image and elemental maps of Co, Cr, Fe, Mn, and Ni for a single nanoparticle, the laser ablation area is located on the left side of the image with all scale bars represent 25 nm.[67] Copyright 2013, Wiley-VCH.

-

Figure 6.

a Au-Rh phase diagram showing the immiscibility between the solid phases. b Schematic of the synergistic effect in alloys versus linear/simple addition effect in the immiscible mixture.[68] Copyright 2013, Cell Press. c Schematic comparison of phase-separated heterostructures synthesized by a conventional slow reduction procedure (slow kinetics) versus solid-solution HEA-NPs synthesized by the CTS method (fast kinetics).[71] Copyright 2018, Science. d Thermal shock alloying process using a milliseconds-scale high-temperature synthesis. e High-entropy alloy CoMoFeCoNi (HEA-CoxMoy) nanoparticles, digital image of the samples before and during the thermal shock synthesis. f The intensity of the emitted light from the shock at different wavelengths. g Typical temperature profiles during the thermal shocks as determined from the emission intensities.[72] Copyright 2020, Nature. h The hybrid MD-MC simulation approach for forming an Ru-5 MEA-NP at

1500 K. The high temperature promotes uniform mixing, while the high entropy stabilizes the structure. TEM images show the uniform size and dispersion of i Ru-4 and j Ru-5 MEA-NPs on carbon nanofibers.[71] Copyright 2020, Science. k Hematic diagram of the FMBP experimental setup for the synthesis of HEA-NPs. l Chematic diagrams for the synthesis of homogeneous and phase-separated HEA-NPs by FMBP and FBP strategies, respectively.[70] Copyright 2020, Nature. -

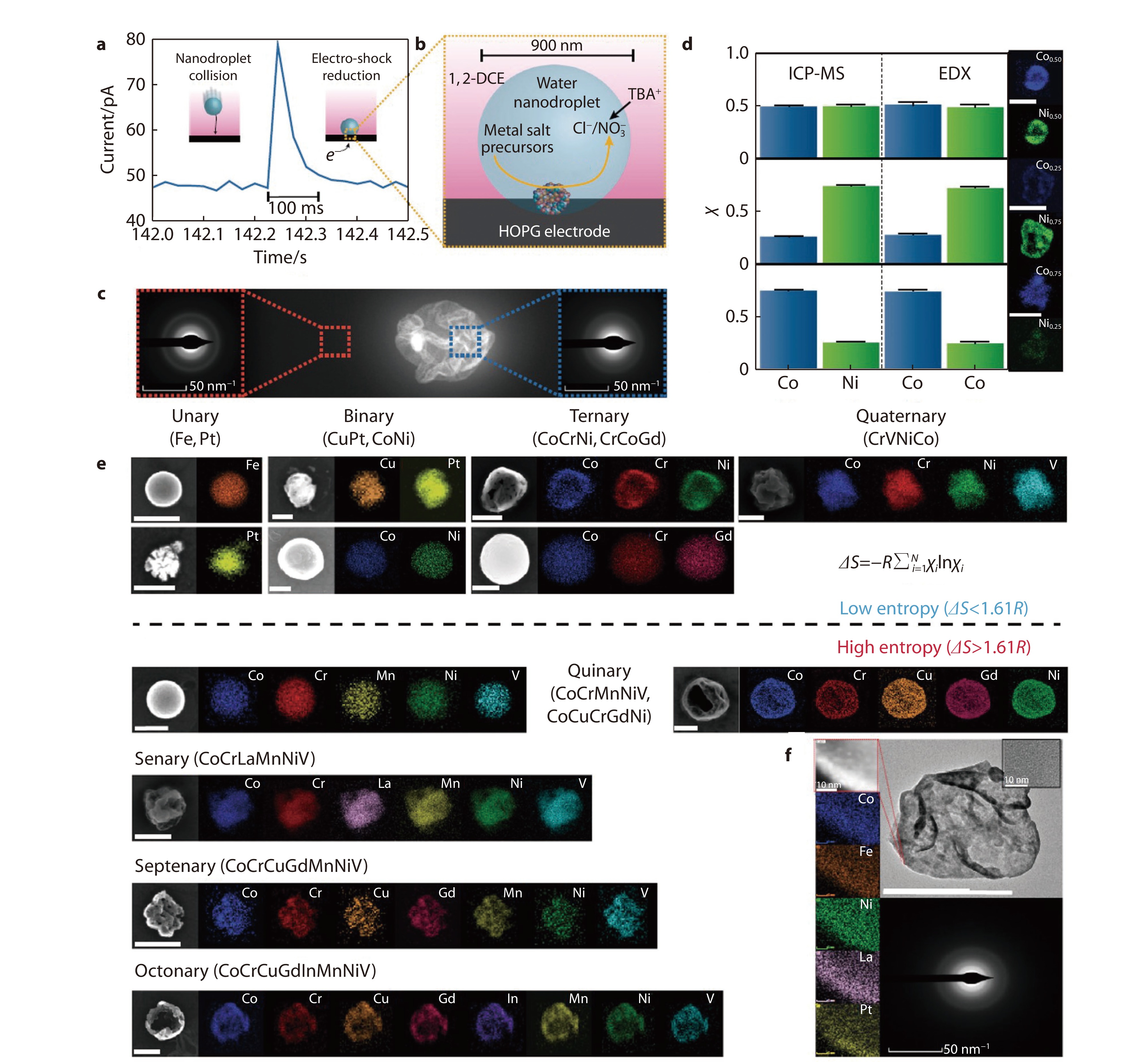

Figure 7.

a Nodroplet-mediated electrodeposition overview for controlling NP stoichiometry and microstructure. Current transient corresponding to the collision of a single nanodroplet onto a carbon fiber UME (rUME = 4 μm) biased at −0.4 V vs. Ag/AgCl. Nanodroplet contents are fully (>98%) reduced within 100 ms, facilitating disordered co-deposition of various metal precursors. b Epresentation of a nanodroplet collision event highlighting the rapid NP formation at the water/substrate interface and the charge balance ensured by the transfer of TBA+ across the oil/water interface. c Amorphous microstructure is confirmed by a lack of crystallinity at high resolution and the presence of diffuse rings on the SAED pattern. d-f Orrelated ICP-MS and EDX results on Co0.5Ni0.5, Co0.25Ni0.75, and Co0.75Ni0.25 MG-NPs confirming precise control over NP stoichiometry.[82] Copyright 2013, Nature.

-

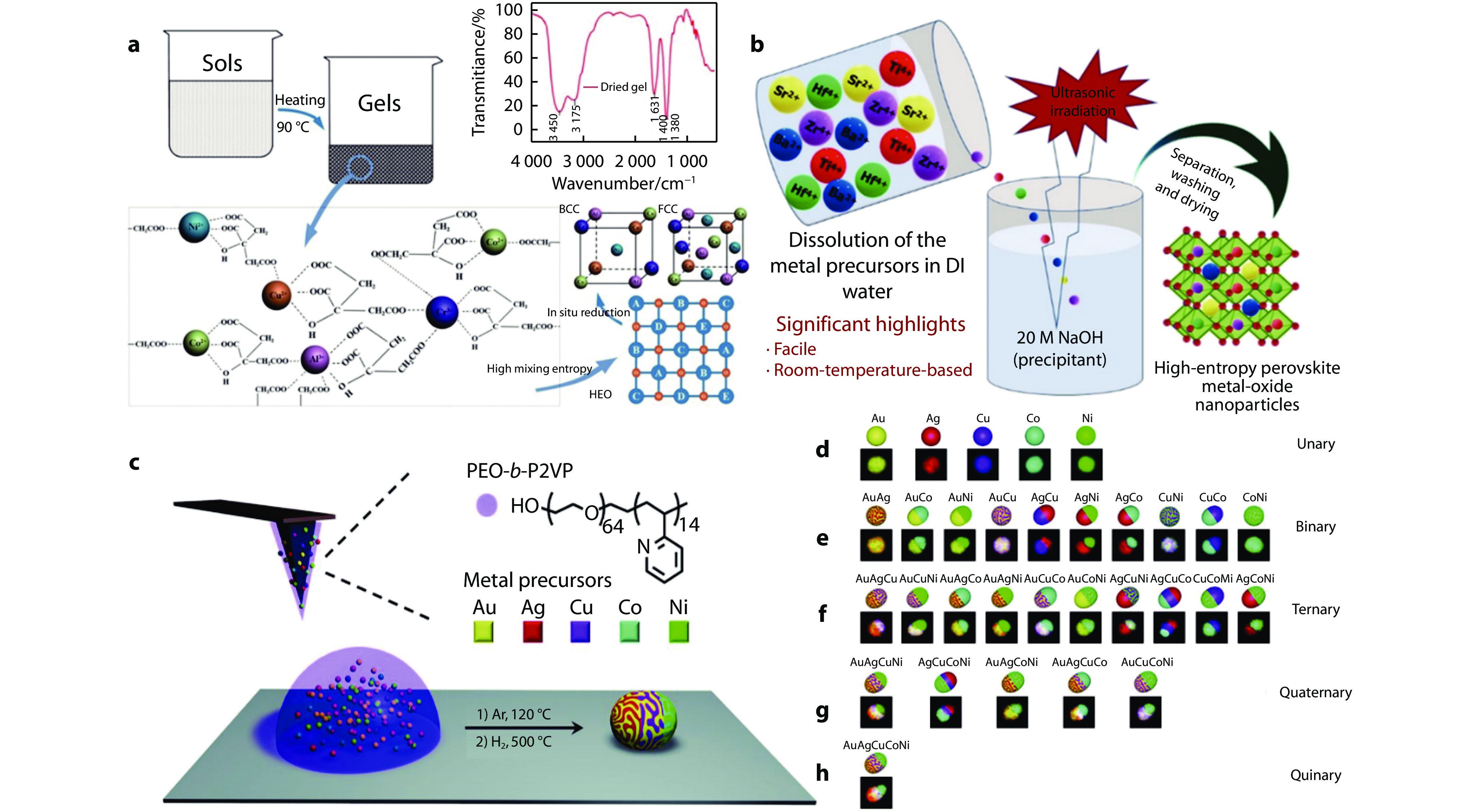

Figure 8.

a, Schematic illustration of the sol–gel combustion process b, the FTIR pattern for the dried gel).[83] Copyright 2017, Nature, c, Schematic illustration of the sonochemical-based synthesis of HEPO- 5-NPs (BaSr(ZrHfTi)O3).[84] Copyright 2019, Wiley-VCH. The SPBCL-mediated synthesis of multimetallic NPs and a five-element library of unary and multimetallic NPs made via this technique, d, Scheme depicting the process: A polymer loaded with metal ion precursor is deposited onto a substrate in the shape of a hemispherical dome via dip-pen nanolithography, EDS mapping of e Unary NPs, f Binary NPs, g Ternary, h, Quaternary and i, Quinary NPs. [86] Copyright 2016, Science.

-

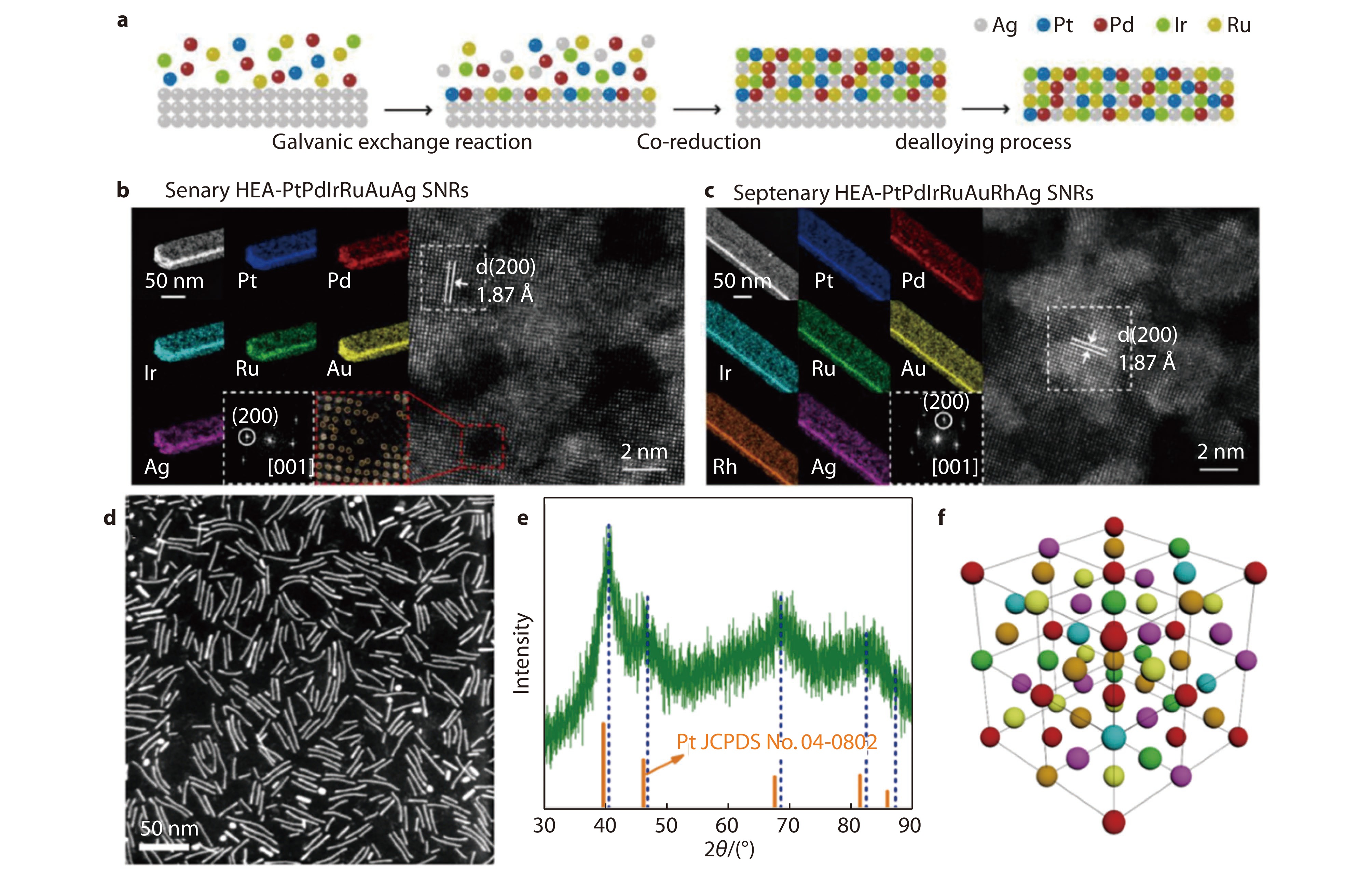

Figure 9.

a, Schematic illustration of the proposed galvanic exchange, co-reduction, and dealloying pathways in the synthesis of HEA SNRs. b, HAADF-STEM image, EDS element mapping images, and high-resolution HAADF-STEM image of a senary HEA-PtPdIrRuAuAg SNR, c, HEA-PtPdIrRuAuRhAg SNR with the corresponding FFT pattern taken from the white dashed square.[4] Copyright 2022, American Chemical society. d, HAADF-STEM image, e, XRD pattern, f, Crystal structure of HEA nanowires.[88] Copyright 2021, Nature.

-

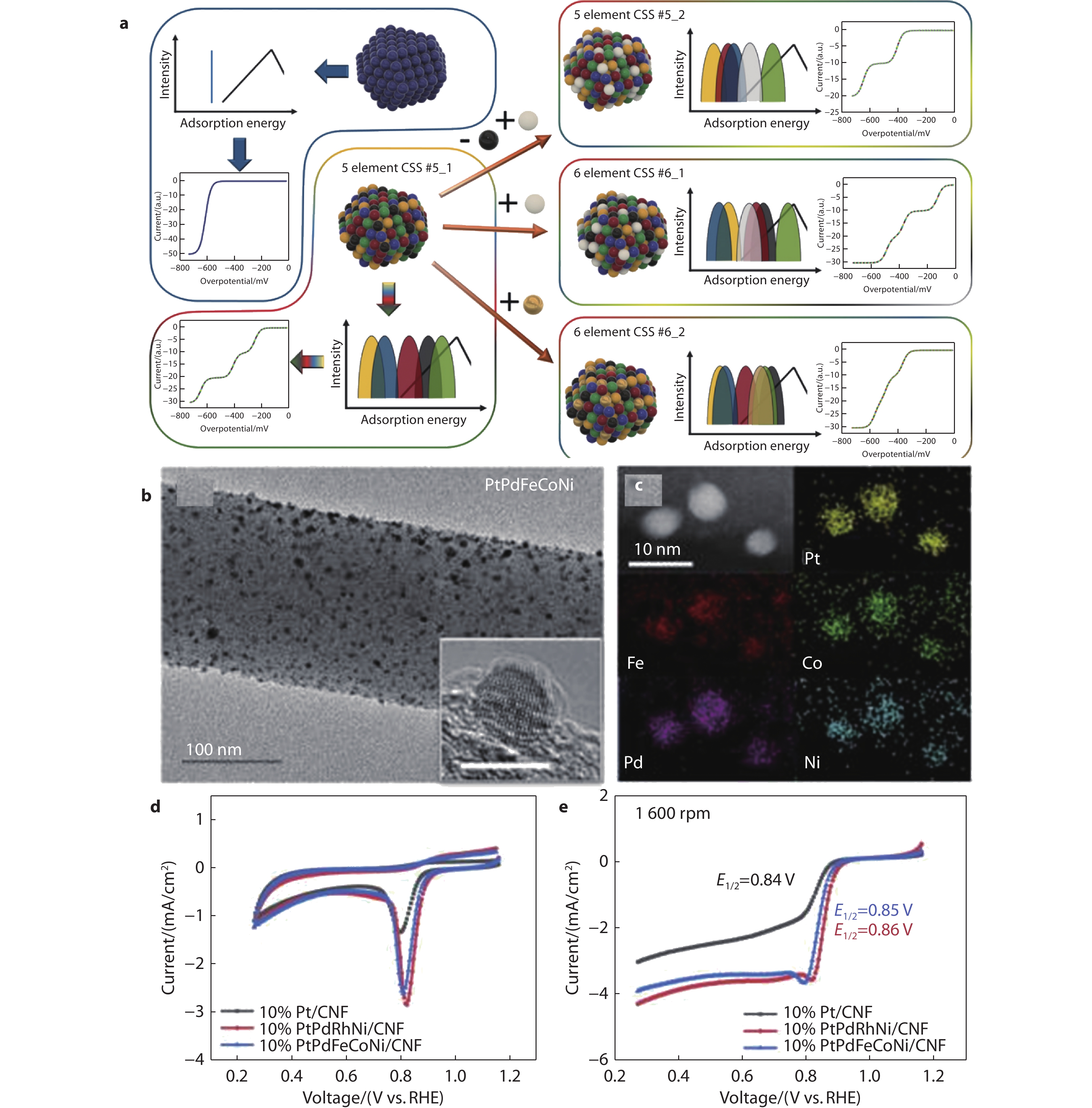

Figure 10.

a Schematic exemplary illustration of correlations between CSS nanoparticle structure, its effect on the adsorption energy distribution pattern and the respective electrochemical response in the kinetic region.[92] Copyright 2019, Wiley-VCH. TEM image b-c and elemental maps of PtPdFeCoNi with uniform small size and alloy structure, inset is a high-resolution TEM image of PtPdFeCoNi. d-e Electrochemical analysis of PtPdRhNi, PtPdFeCoNi, and a control Pt catalyst for ORR.[95] Copyright 2020, PNAS.

-

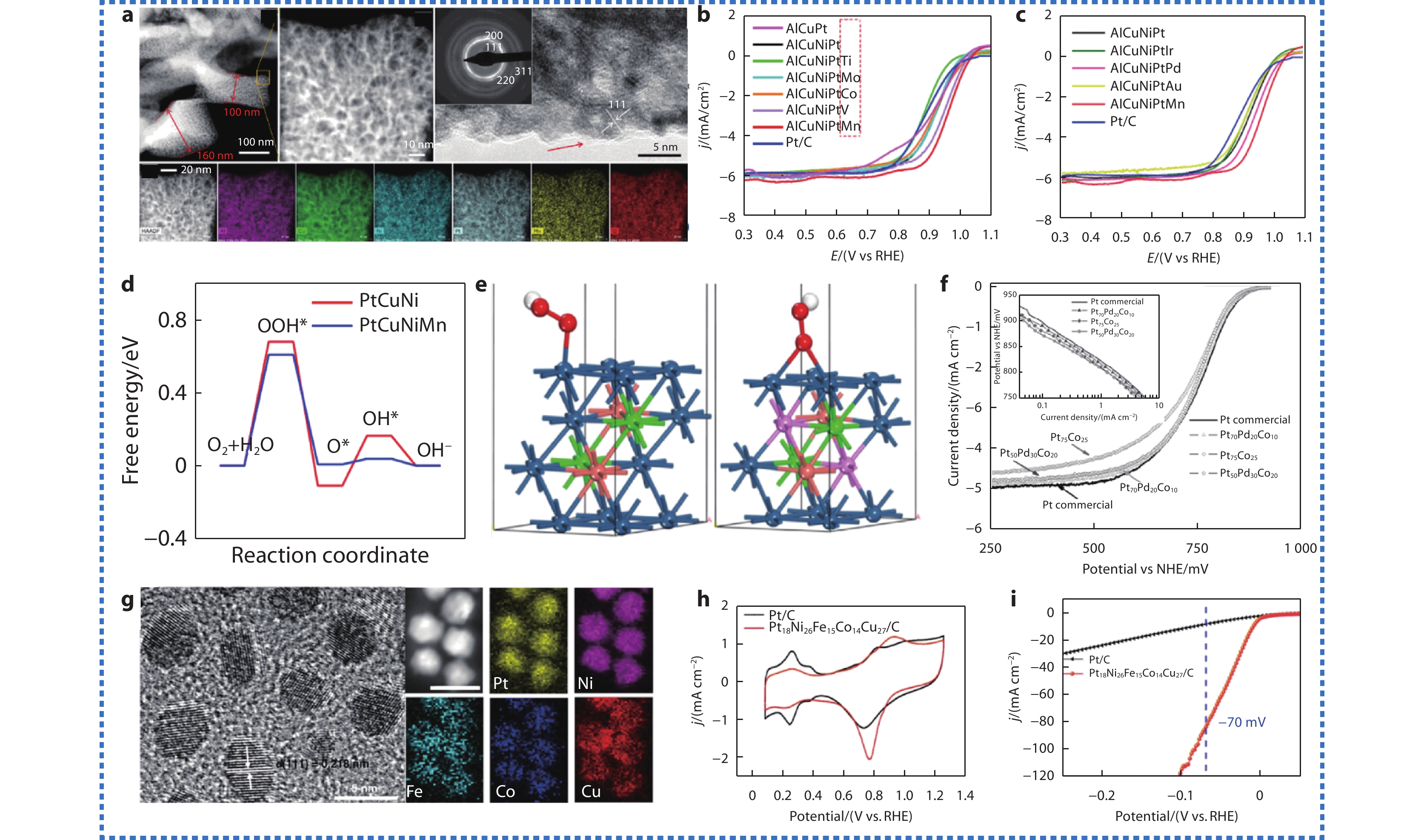

Figure 11.

a STEM images of the np-AlCuNiPtMn at two different magnifications is the corresponding HRTEM and SAED image (inset). Dark field STEM-EDS mapping of the quinary np-HEA. The red arrow indicates the formed thin surface oxides. b-c ORR polarization curves of these samples in O2-saturated 0.1 M KOH solution. d-e Free energy profiles of the ORR steps on the CuNiMnPt and the CuNiPt.[96] Copyright 2020, Elsevier. f Hydrodynamic polarization curves of the Pt75Co25, Pt70Pd20Co10 and Pt50Pd30Co20 samples synthesized by the MW-ST method and commercial Pt with the insets showing the Tafel plots.[97] Copyright 2010, Wiley-VCH. g HRTEM image of Pt18Ni26Fe15Co14Cu27 nanoparticles. h HER in 1 M KOH electrolyte, a CV curves and i HER polarization curves.[98] Copyright 2020, Nature.

-

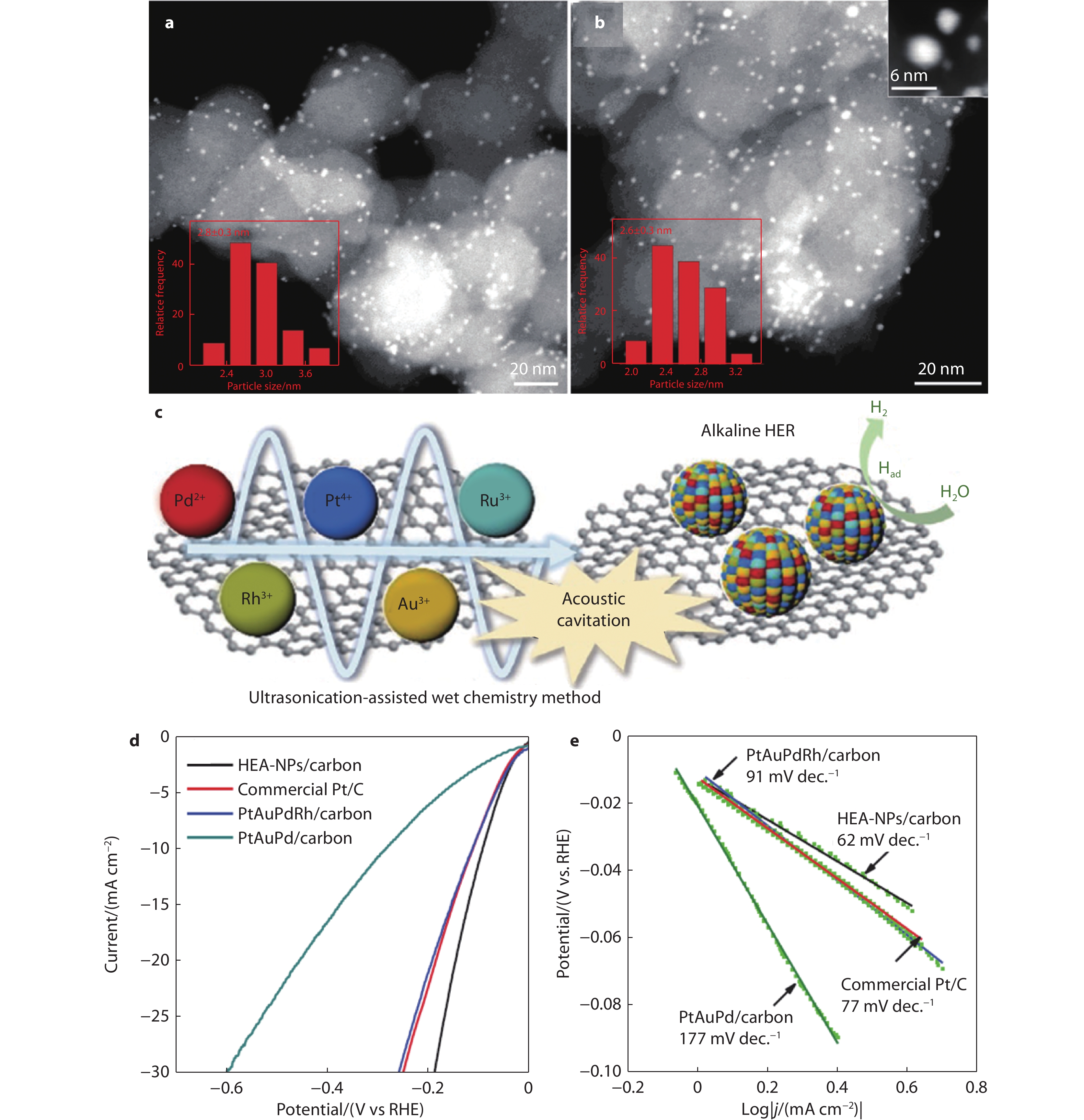

Figure 12.

STEM image of a HEA-NPs/carbon and b HEA-NPs/carbon-700 °C. c Schematic illustration of synthesis of HEA-NPs/carbon (PtAuPdRhRu supported on XC-72 carbon) catalysts and their application in HERs. d Polarization curves and e Tafel plots of HEA-NPs/carbon-700 °C, PtAuPdRh/carbon-700 °C, PtAuPd/carbon-700 °C, and commercial Pt/C (Pt loading = 20 wt%) catalysts in 1.0 M KOH.[105] Copyright 2019, Wiley-VCH.

-

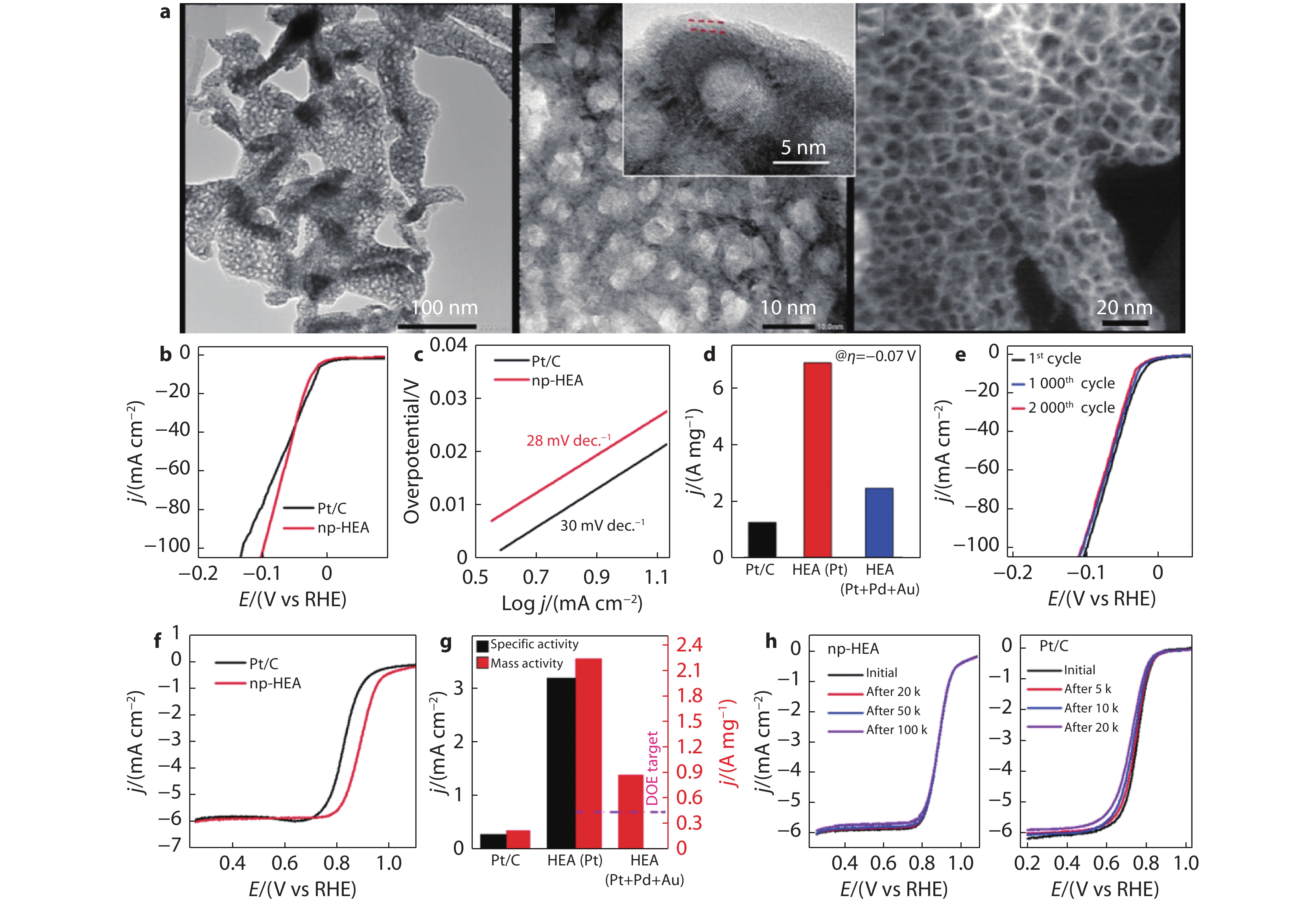

Figure 13.

a TEM images of the dealloyed senary np-HEA at different magnifications. b-d EASA and Pt or Pt+Pd+Au mass activities at 0.9 V and durability after different cycles in O2-saturated 0.1 M HClO4. e High-resolution TEM image of a PdCuFe/C-400 nanoparticle. Inset displays corresponding FFT pattern, f CV and g LSV curves of PdCuM/C-400 (M=non, Fe, Co), Pd/C, and Pt/C catalysts.[110] Copyright 2019, Royal Society of Chemistry.

-

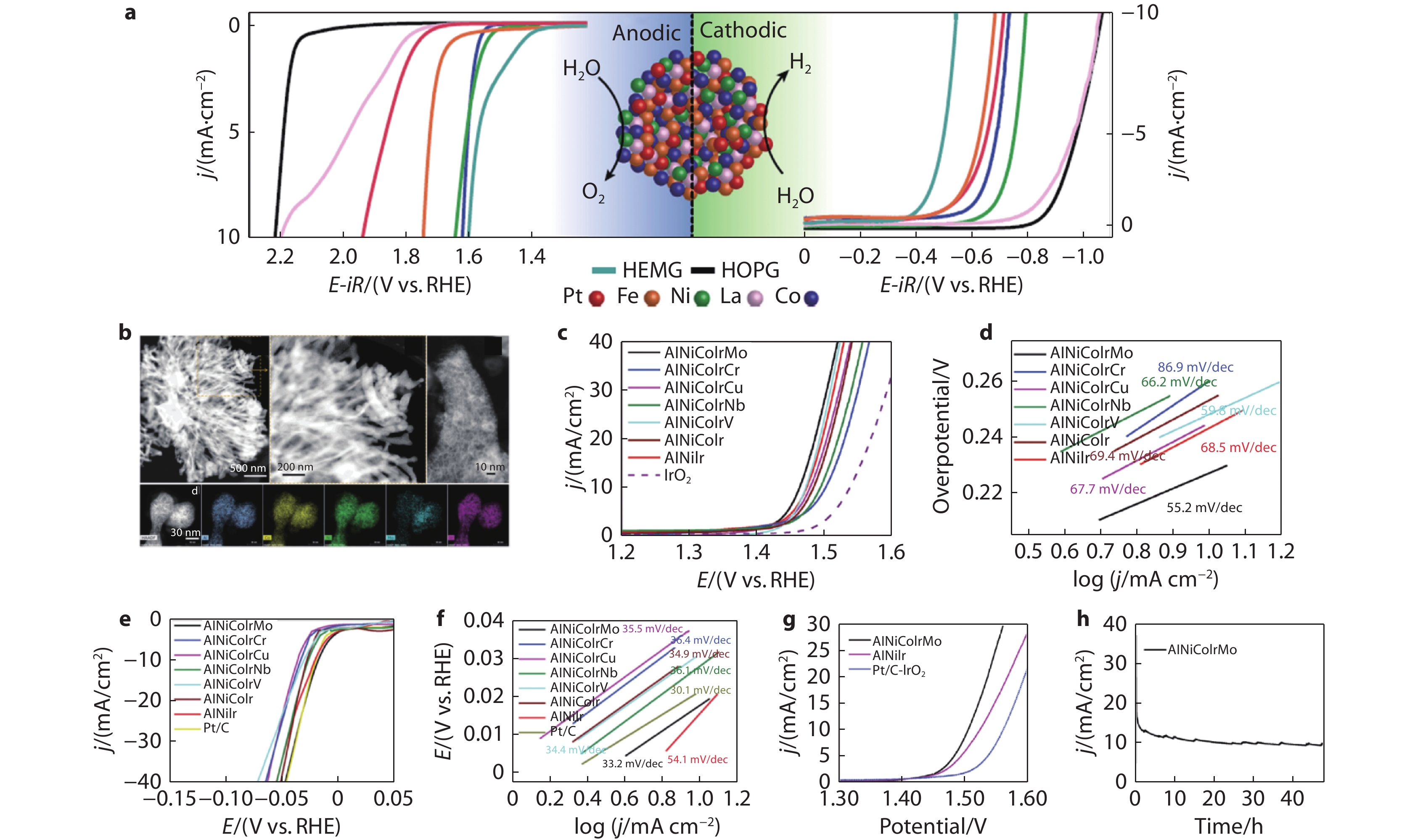

Figure 14.

a Electrocatalytic evaluation of a CoFeLaNiPt HEMG-NP electrocatalyst. Anodic polarization of the HEMG electrocatalyst and its individual components starting from the equilibrium potential of OER, 1.23 V vs. RHE.[82] Copyright 2019, Nature. b STEM images of the dealloyed np-AlNiCoIrMo at different magnifications and STEM-EDS mapping of the quinary np-HEA. c OER polarization and d Tafel curves of all these prepared samples and IrO2. Comparison of Ir mass activities at 1.5 V with literature data, e HER polarization, f corresponding Tafel curves of all these prepared samples and Pt/C. g Identical two-electrode system for overall water splitting, and h the long-term durability test of the np-AlNiCoIrMo sample at 1.52 V in 0.5 M H2SO4 solution.[113] Copyright 2019, Wiley-VCH.

-

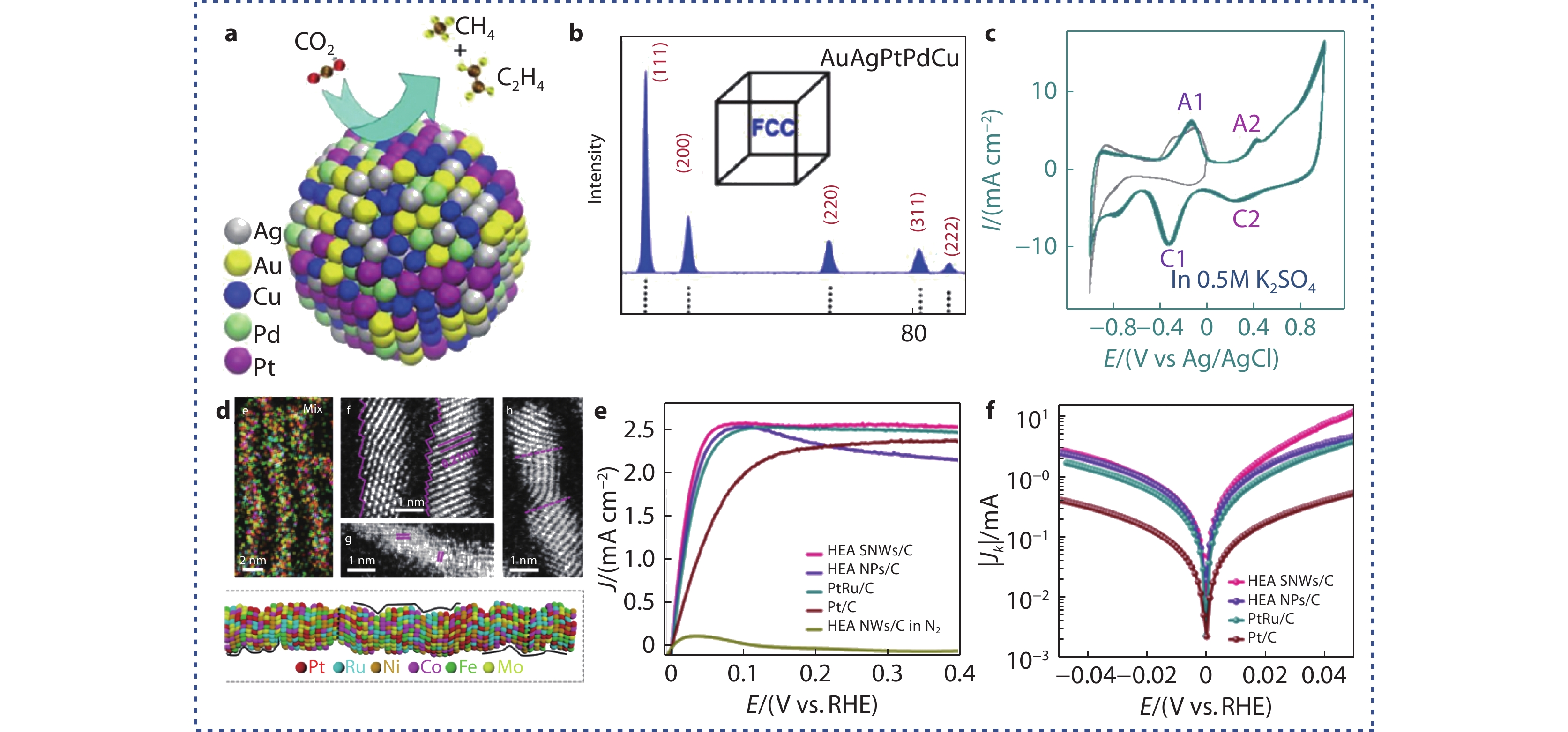

Figure 15.

a Schematic of the catalysis reaction demonstrated in current work. b X-ray-diffaraction pattern of HEA alloy NPs (AuAgPtPdCu nanoparticles). c Chemical homogeneity of Au, Ag, Pt, Pd and Cu.[116] Copyright 2019, American Chemical Society. d HAADF-STEM-EDS elemental mappings and Aberration-corrected HR-STEM images. e Polarization curves in H2-saturated 0.1 M KOH. f Tafel plots of f HEA SNWs/C.[88] Copyright 2021, Nature.

-

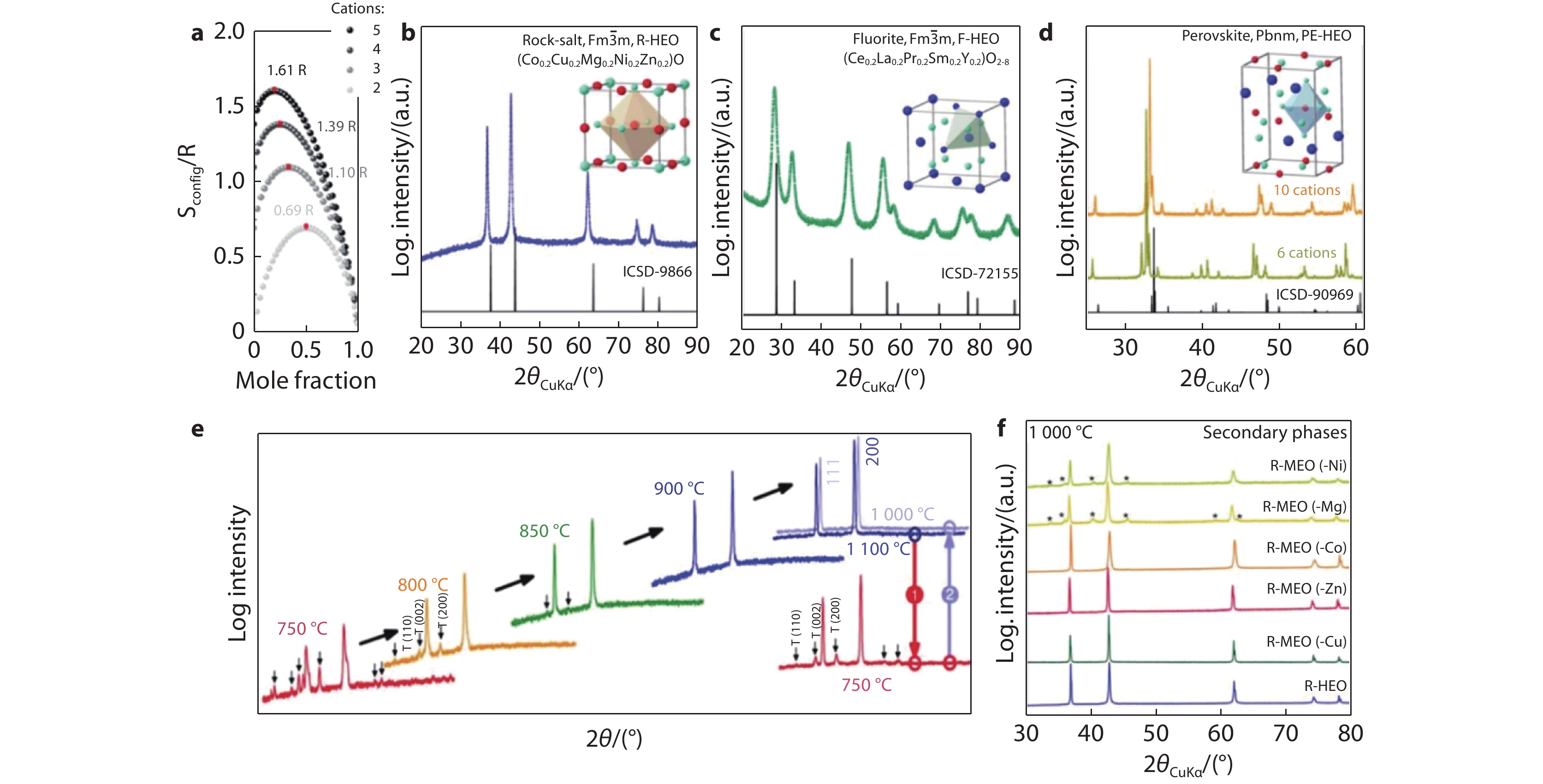

Figure 16.

a, XRD patterns of HEO systems: b, R-HEO, c, F-HEO, and d, Reversible phase transformation as an indication of the entropy stabilization effect. e, XRD patterns of different types of R-MEOs. [119] Copyright 2019, Wiley-VCH.

-

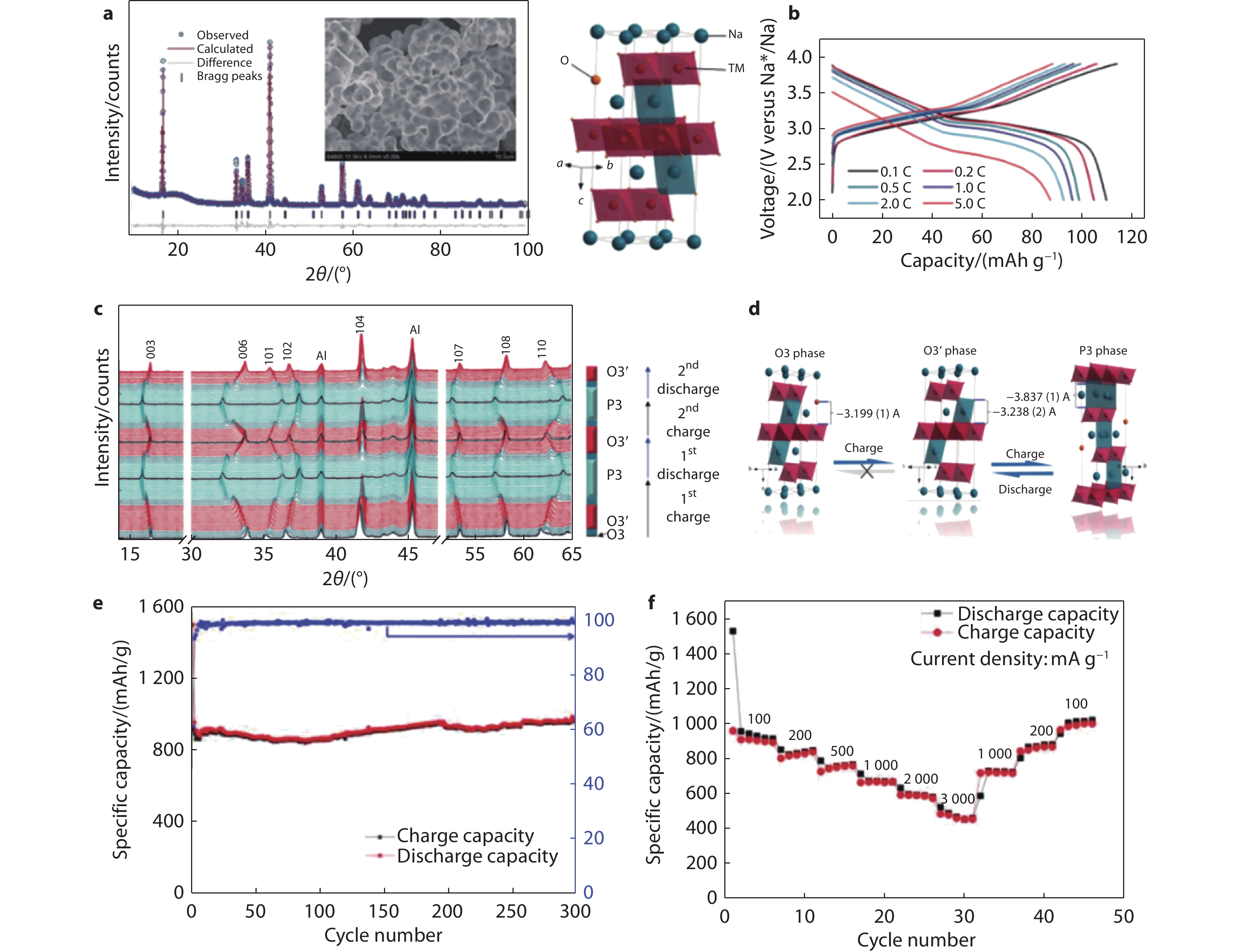

Figure 17.

a XRD of HEO, b Long-term cycling performance and Coulombic efficiency of R-HEO with nanometer-sized particles. c in-situ XRD and Specific capacity over 100 cycles and d the first lithiation profiles of different compounds.[133] Copyright 2018, Elsevier. e-f Rate performance test of nanometer-sized R-HEO with the specific current given in units of mA g−1.[119] Copyright 2018, Wiley-VCH.

-

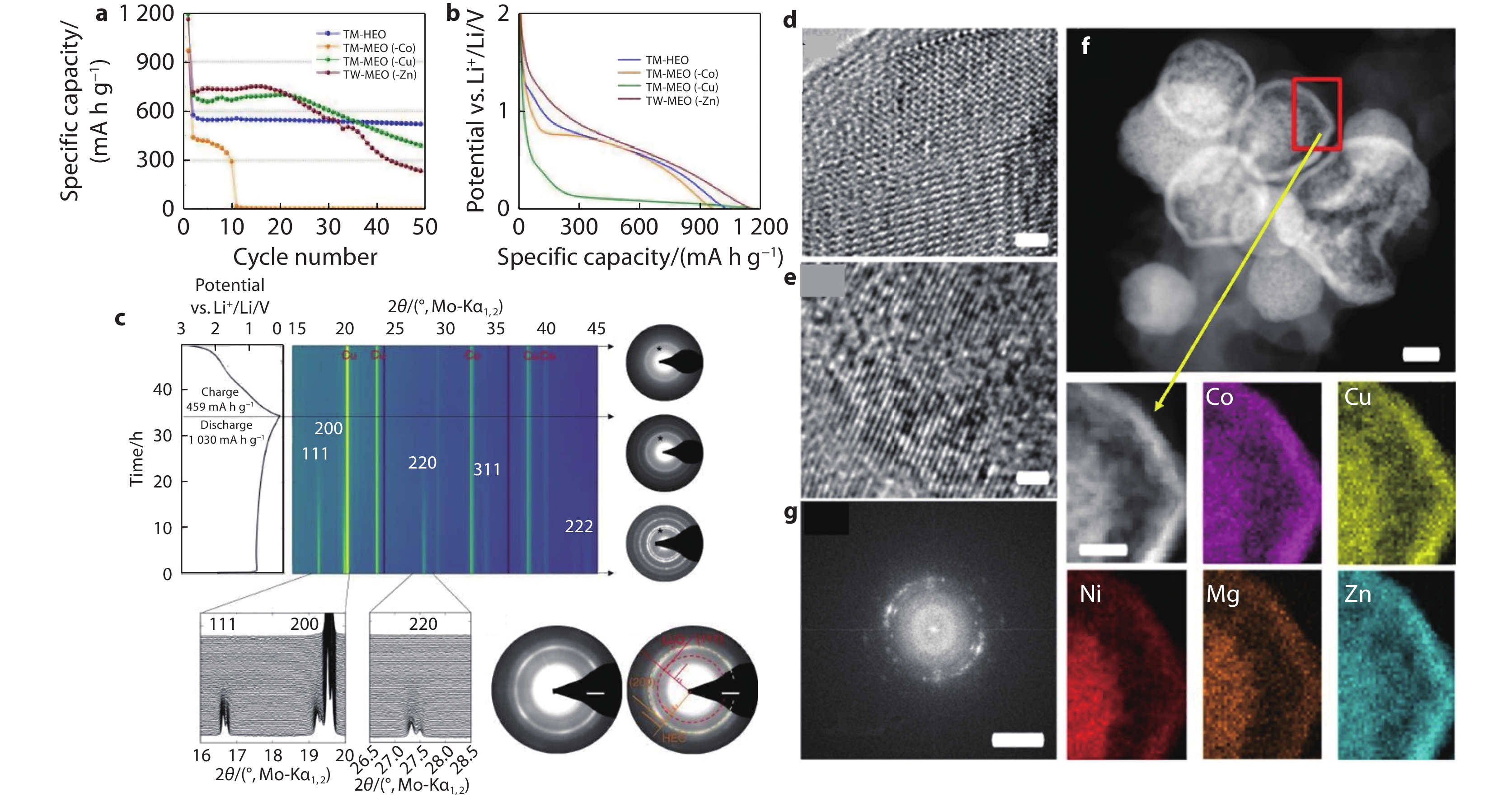

Figure 18.

a Stable capacity retention at 50 mA g‒1, while the materials without Zn and Cu reveal severe capacity degradation. The material without Co fails completely after 10 cycles. b Discharge (lithiation) profiles of the first cycle for the different compounds. c Operando XRD on TM-HEO, during the first full lithiation/delithiation cycle. The black lines with arrows indicate the as-prepared, fully lithiated and fully delithiated states as a function of time. d-e HRTEM and f EDX analysis of the active material and g SAED analysis for cycled TM-HEO, respectively.[122] Copyright 2019, Nature.

-

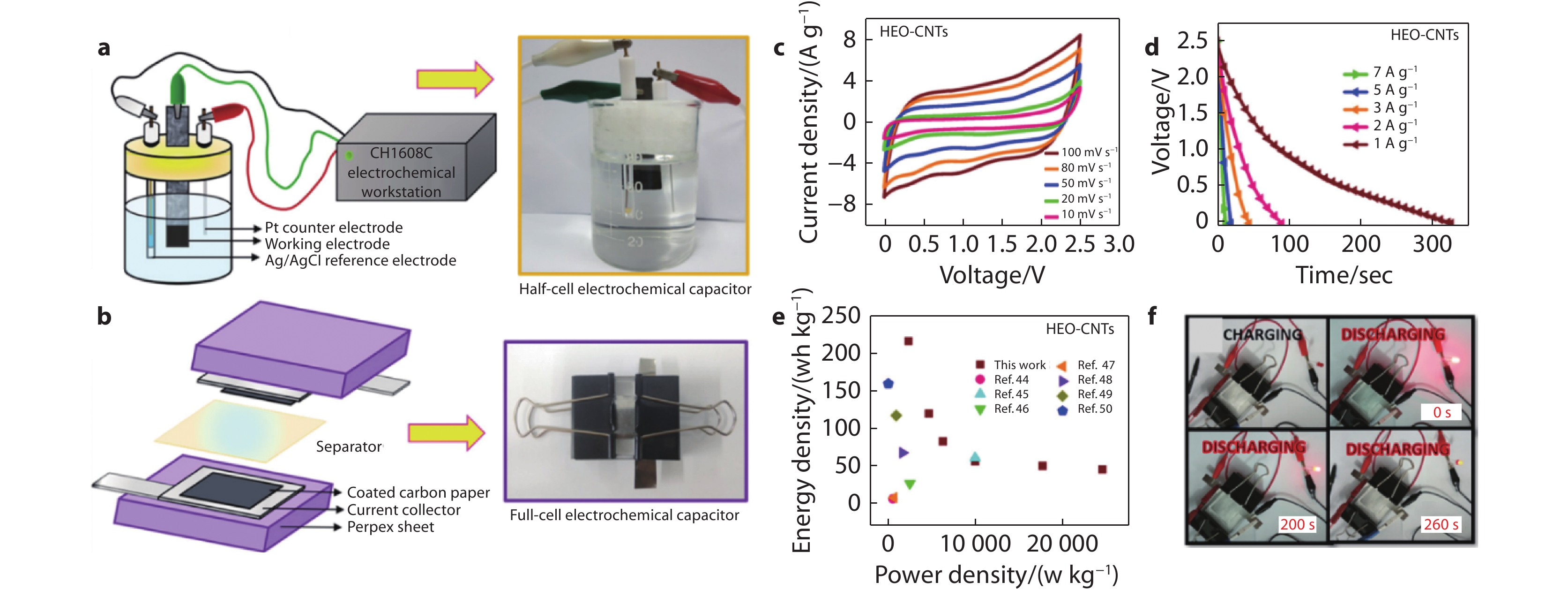

Figure 19.

Schematic illustration of the a half-cell and b full-cell EC, c CV plots of the HEO−CNT nanocomposite-based fc-EC using the [BMIM][TFSI] electrolyte at different scan rates. d GD plots of HEO−CNT-based fc-EC using the [BMIM][TFSI] electrolyte at different current densities. e Corresponding Ragone plot and comparison with previous reports and f lighting one red LED and valuation at a different stage.[143] Copyright 2019, American Chemical Society.

Hassina Tabassum is a Postdoctoral Associate at the University at Buffalo, the State University of New York (SUNY), USA. Before this, she was a Boya Postdoctoral fellow at Peking university. She has published several high-quality research articles. Her publications have been cited more than 3400 times with H-index of 29. She is several award recipients, including Peking University’s best academic award 2016, Top Ten Best Young Researchers Award of Peking University 2017, Joule Star Talk Award 2019, and the International young scientist funding award 2020. Her research interests are based on the fabrication of advanced nanomaterials for electrochemical energy conversion and storage devices.

Hassina Tabassum is a Postdoctoral Associate at the University at Buffalo, the State University of New York (SUNY), USA. Before this, she was a Boya Postdoctoral fellow at Peking university. She has published several high-quality research articles. Her publications have been cited more than 3400 times with H-index of 29. She is several award recipients, including Peking University’s best academic award 2016, Top Ten Best Young Researchers Award of Peking University 2017, Joule Star Talk Award 2019, and the International young scientist funding award 2020. Her research interests are based on the fabrication of advanced nanomaterials for electrochemical energy conversion and storage devices.  Xiaoxuan Yang was a visiting Ph.D. student at the University at Buffalo, the State University of New York (SUNY). She obtained her Ph.D. at Northeast Normal University in 2021. Currently, she is a postdoc at Zhejiang University. Her research interests mainly focus on the design, synthesis, and characterization of functional nanomaterials for electrochemical energy storage and conversion.

Xiaoxuan Yang was a visiting Ph.D. student at the University at Buffalo, the State University of New York (SUNY). She obtained her Ph.D. at Northeast Normal University in 2021. Currently, she is a postdoc at Zhejiang University. Her research interests mainly focus on the design, synthesis, and characterization of functional nanomaterials for electrochemical energy storage and conversion.  Ruqiang Zou is currently a full professor and dean of School of Materials Science and Engineering, Peking University, P. R. China. He received his Ph.D. in engineering in 2008 from Kobe University and the National Institute of Advanced Industrial Science and Technology, Japan. He held the JSPS younger scientist during his doctoral course and was a director's postdoc fellow at Los Alamos National Laboratory from 2008 to 2010. He was awarded the Outstanding Young Scientist Foundation of NSFC and Changjiang Scholar. His research interests focus on the controllable preparation of hierarchically porous functional materials for energy and environmental applications.

Ruqiang Zou is currently a full professor and dean of School of Materials Science and Engineering, Peking University, P. R. China. He received his Ph.D. in engineering in 2008 from Kobe University and the National Institute of Advanced Industrial Science and Technology, Japan. He held the JSPS younger scientist during his doctoral course and was a director's postdoc fellow at Los Alamos National Laboratory from 2008 to 2010. He was awarded the Outstanding Young Scientist Foundation of NSFC and Changjiang Scholar. His research interests focus on the controllable preparation of hierarchically porous functional materials for energy and environmental applications.  Gang Wu is a Professor of Chemical Engineering at the University at Buffalo (UB), SUNY. He obtained his B.S. in 1997 and Ph.D. in 2004 at the Harbin Institute of Technology. After postdoctoral training at Tsinghua University, the University of South Carolina, and Los Alamos National Laboratory (LANL), he became a staff scientist at LANL in 2010. He joined UB in 2014 as an assistant professor and was promoted to tenured associate professor in 2018 and a full professor in 2020. He has published more than 300 papers with 39000 citations, leading an H-index of 106. He is a Highly Cited Researcher ranked by Thomson Reuters, Clarivate Analytics since 2018. His research interests are electrochemical energy science and technology, with an emphasis on advanced electrocatalysis for fuel cells, water electrolzyers, CO2 reduction, and chemical electrosynthesis.

Gang Wu is a Professor of Chemical Engineering at the University at Buffalo (UB), SUNY. He obtained his B.S. in 1997 and Ph.D. in 2004 at the Harbin Institute of Technology. After postdoctoral training at Tsinghua University, the University of South Carolina, and Los Alamos National Laboratory (LANL), he became a staff scientist at LANL in 2010. He joined UB in 2014 as an assistant professor and was promoted to tenured associate professor in 2018 and a full professor in 2020. He has published more than 300 papers with 39000 citations, leading an H-index of 106. He is a Highly Cited Researcher ranked by Thomson Reuters, Clarivate Analytics since 2018. His research interests are electrochemical energy science and technology, with an emphasis on advanced electrocatalysis for fuel cells, water electrolzyers, CO2 reduction, and chemical electrosynthesis.

DownLoad:

DownLoad: